FFF & FDM 3D Printing Services

Get durable, functional components in production-grade materials like Ultem, PC-ABS, and carbon-filled nylons.

Is FFF & FDM Printing Right for Your Part?

How FFF & FDM Works

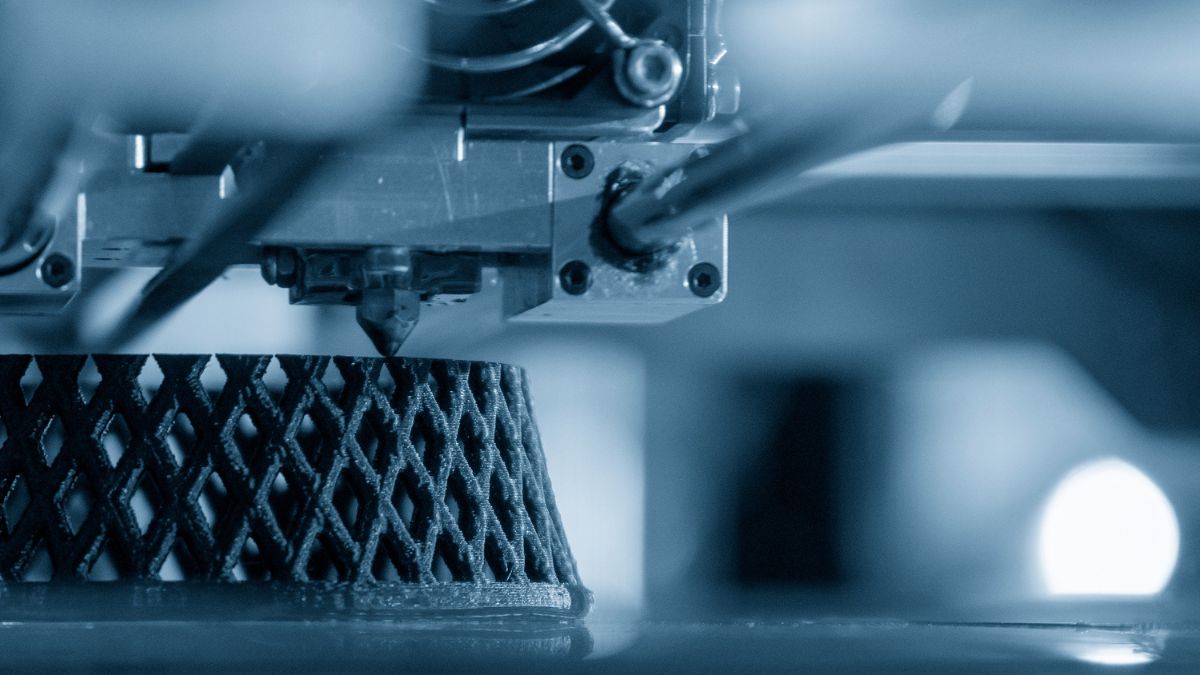

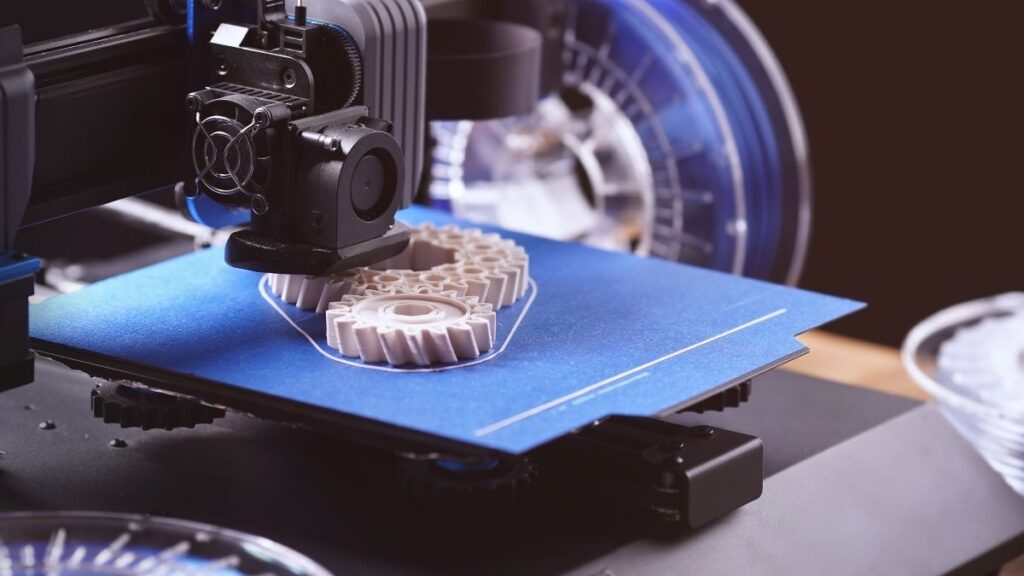

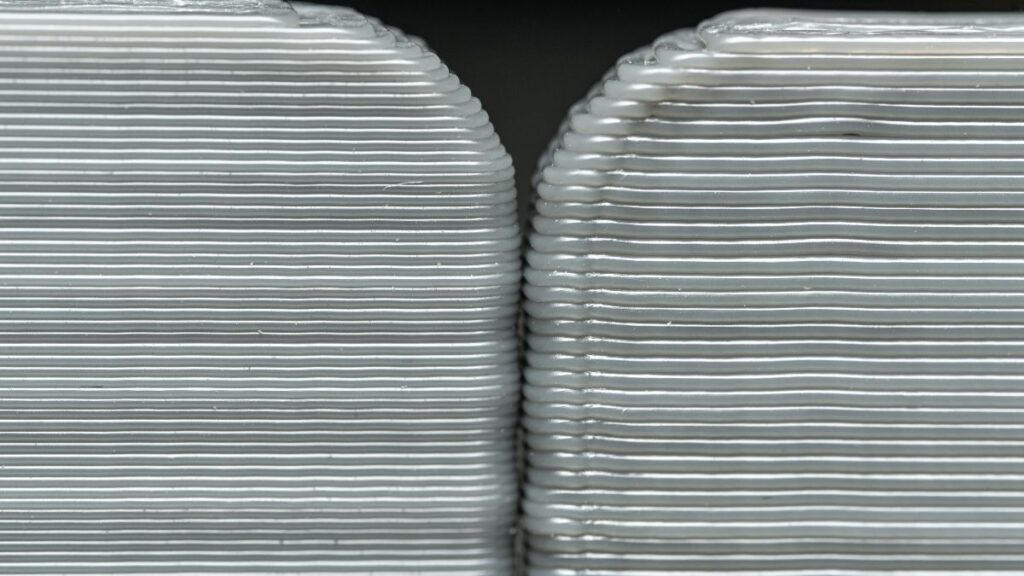

FFF (fused filament fabrication), also known as FDM (fused

deposition modeling), extrudes heated thermoplastic filament

layer-by-layer to build robust parts. It’s a reliable way to

produce strong, accurate components with fast turnarounds

and broad material options.

What are FFF & FDM Ideal For?

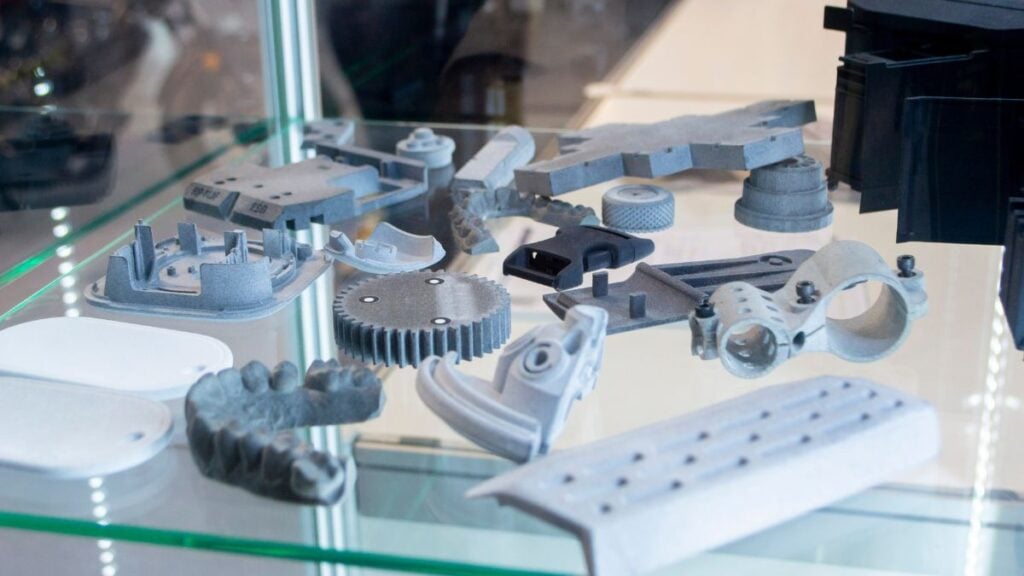

- Manufacturing aids, such as jigs, fixtures, drill guides, and

go/no-go gauges - Large, flat, or robust geometries that benefit from strong

thermoplastics - Functional prototypes and low-volume end-use parts that must

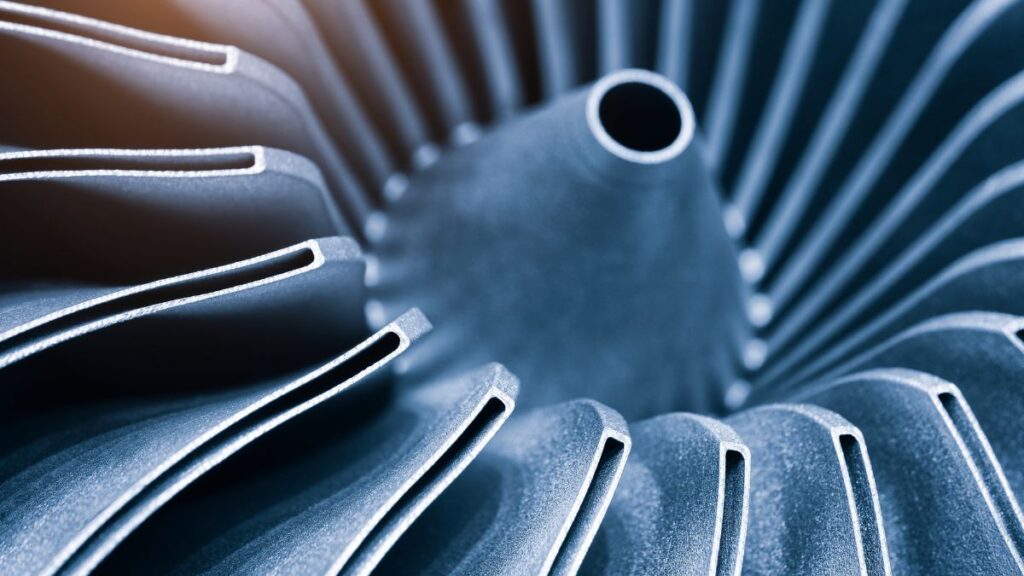

perform in real environments - Industries, such as aerospace, industrial, medical, and high

tech, where consistency and documentation matter

At a Glance: Advantages vs. Other Processes

At A3D Manufacturing, we offer application-first guidance and hybrid

workflows. Our approach is process-agnostic: we guide you to the

right method for your outcome, not just what’s convenient.

FFF & FDM 3D printing advantages include:

- Tough, end-use thermoplastics (such as PC-ABS, Ultem, and

Nylon 12/CF) for impact, heat, and chemical resistance - Large build volumes for sizable parts and fixtures

- Predictable tolerances and practical design rules for repeatability

- Faster iterations without tooling

- Easy design updates across builds

FFF & FDM Capabilities & Technical Specifications

Lead Times

- Standard 3-4 days

- Expedited as soon as next-day

Tolerances

- X/Y: 0.005″, or 0.002 in/in, whichever is greater

- Z: Above tolerances +/- a layer height

Layer Thickness

- 50–500 μm (material-dependent)

Build Envelope

- Composite printer 330 × 270 × 200 mm (XYZ)

- Others up to 36″ × 24″ × 36″ (XYZ)

Materials: Fiber

- Carbon fiber

- Kevlar

- HSHT fiberglass

- Fiberglass

Materials: Thermoplastics

- Carbon fiber

- Kevlar

- HSHT fiberglass

- Fiberglass

- Polycarbonate

- PC-ISO (medical-grade)

- PC-ABS

- Ultem 9085

- Ultem 1010

Post-Processing Options

- Painting

- Inserts (including captured hardware and review required)

- Vapor smoothing

- Plus downstream finishes available through our broder post

processing cell

Quality & Compliance

AS9100 • ISO 9001:2015 • ITAR Registered

We apply rigorous certification standards to every project,

ensuring you receive the highest quality products on time, every

time. You can expect your parts to route through A3D

headquarters in Phoenix, Arizona for final QA – no blind drop

shipping – so you get predictable outcomes with documentation

when needed.

Why this matters to you

- Engineers: tighter control, fewer surprises, faster validation

- Startups: scalable production without new vendor risk

- Supply Chain: traceability, documentation, and consistent delivery from a single accountable partner

Common FFF & FDM 3D Printing FAQs

We support STEP or STL.

These are our typical guidelines:

- Minimum Wall Thickness: 0.040″ is commonly accepted (dependent on material and nozzle size)

- Minimum Clearance for Asssemblies: 0.020″

- Minimum Feature Size: 0.020″ (dependent on layer height)

- Minimum Hole Diameter: 0.060″ for X/Y axis; 0.040″ for Z axis

- Minimum Unsupported Overhang Angle: 40 degrees

Our pricing correlates to material consumption and printer build tone. Support-reducing orientations, infill

choices, and layer height all impact cost.

Our materials and applications engineers can recommend the right material, process, and post-processing for

your use case – including MJF/SLS/SLA or CNC if those are better fits for cost, weight, or performance.