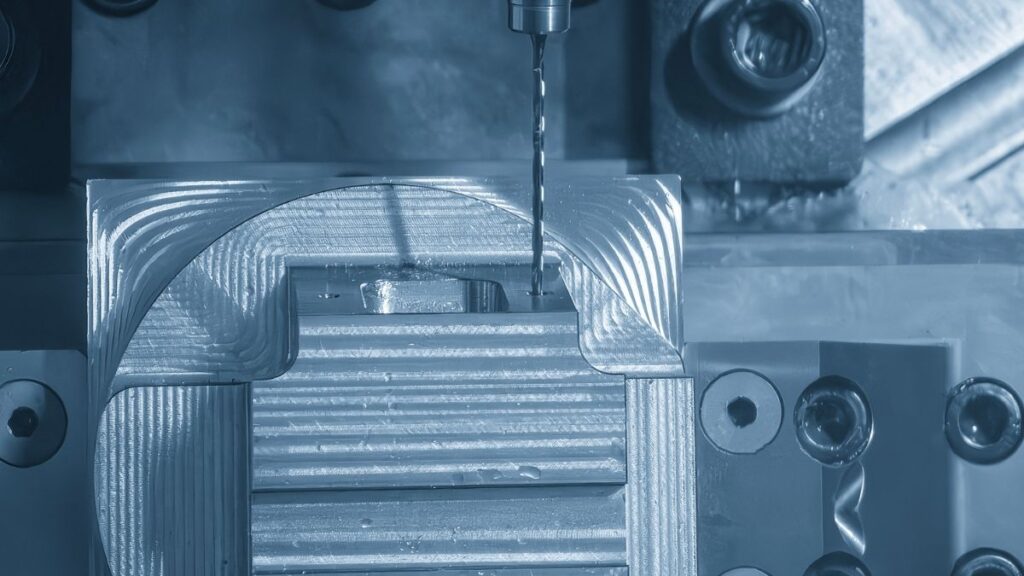

On-Demand CNC Machining Services

Get tight-tolerance CNC parts without the runaround — no minimums, expert manufacturing advice, rigorous quality standards.

AS9100, ISO 9001:2015, and ITAR registered.

Is CNC Machining Right for Your Part?

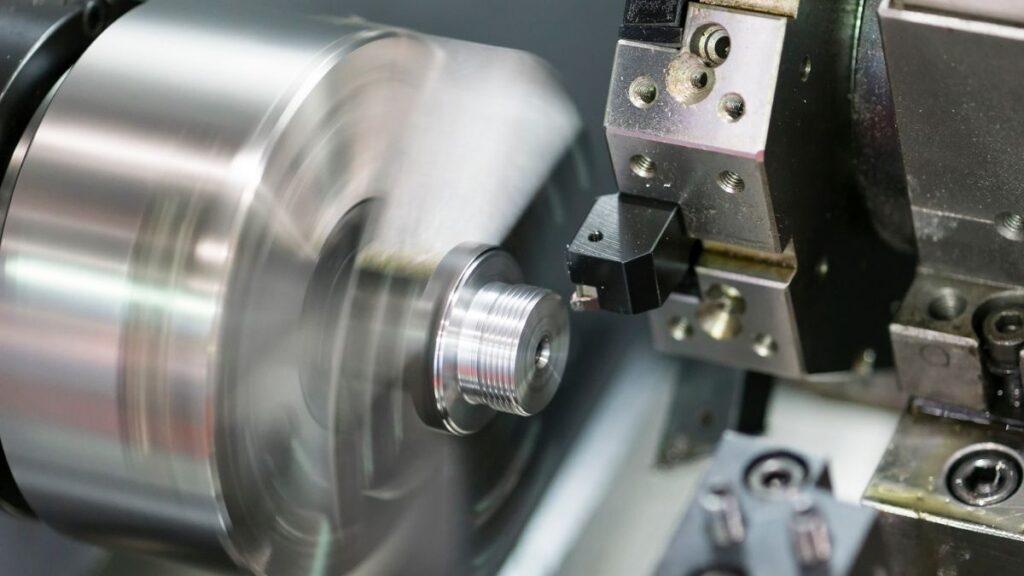

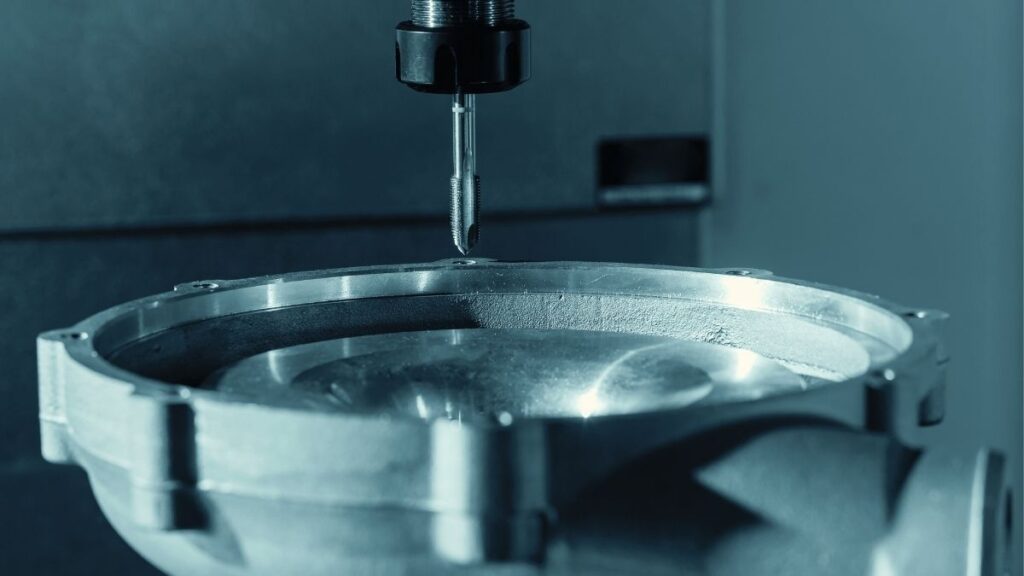

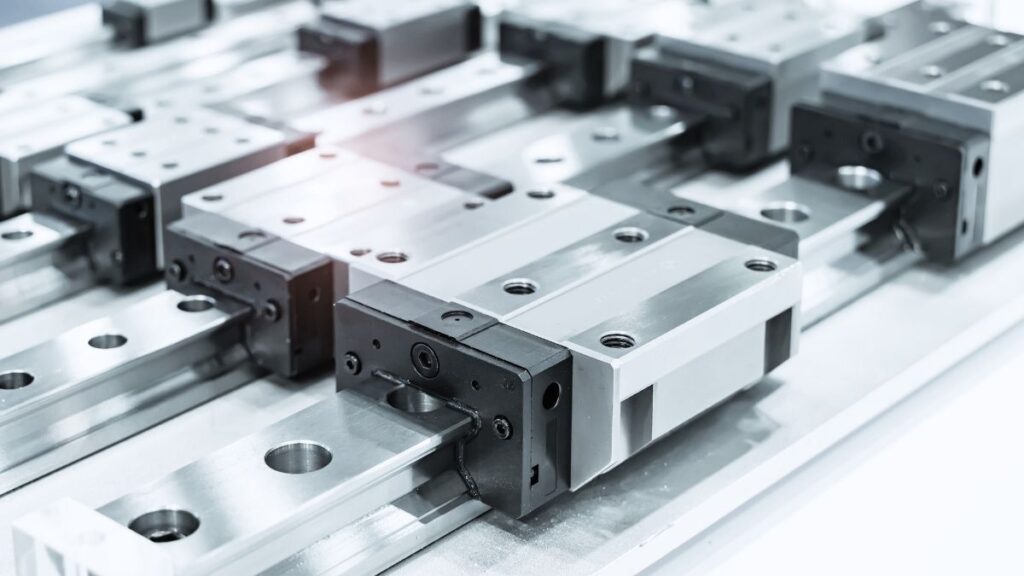

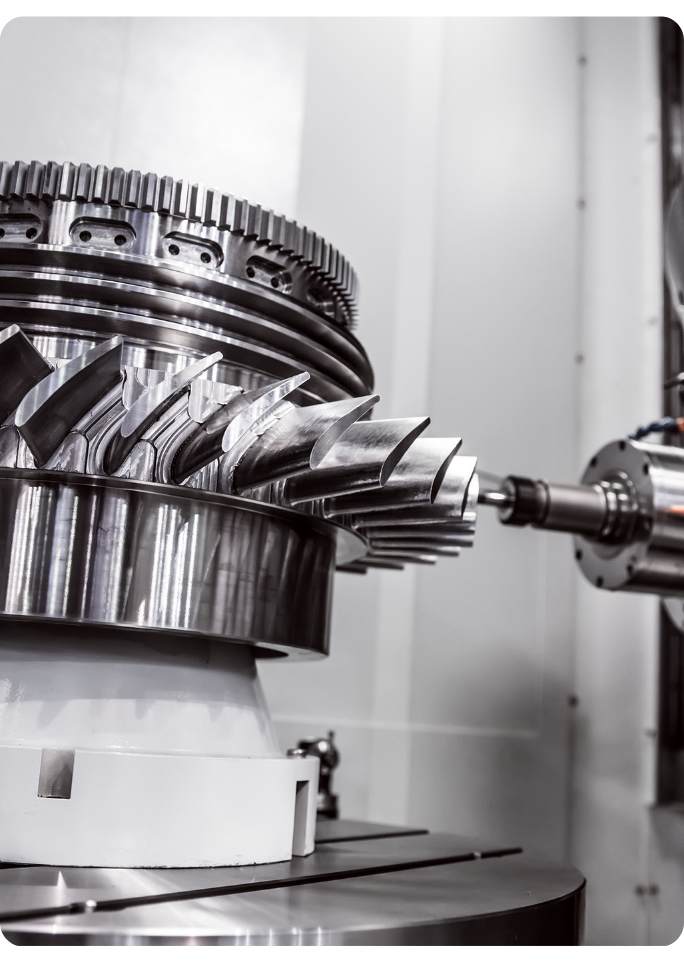

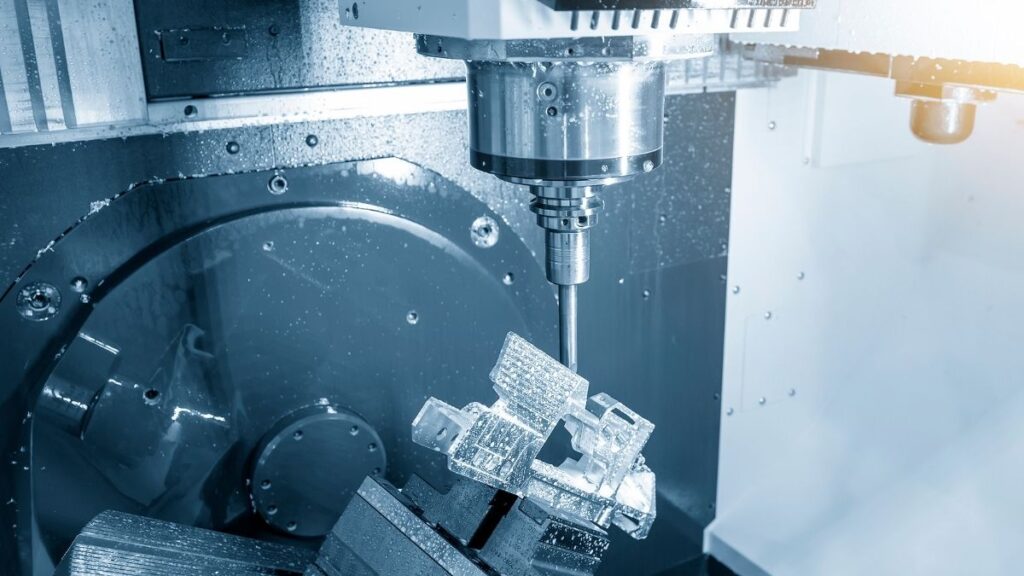

How CNC Machining Works

CNC machining uses computer-controlled tools (mills, lathes, multi-axis platforms) to remove material from metal or plastic stock. Because parts are cut from solid, you get inherent material properties, repeatable tight tolerances, and excellent surface finishes—ideal when performance and precision matter. At A3D, recommendations are application-first and process-agnostic—we’ll point you to CNC, additive, or hybrid depending on the best fit.

What Is CNC Machining Ideal For?

- Functional prototypes that must behave like end-use metals or

engineering-grade plastics - Tight-tolerance components (like bearing fits, sealing interfaces,

and precision enclosures) - Low- to mid-volume production when hard tooling isn’t justified

- Complex geometries requiring multi-axis strategies, threads,

pockets, and datum-driven GD&T - Regulated programs that need traceability, FAIR/AS9102, and

final QA (no blind drop-ship)

Common CNC Applications

Precision Housings & Manifolds

Test Fixtures, Shafts, & Impellers

Surgical Jigs

Aerospace Brackets

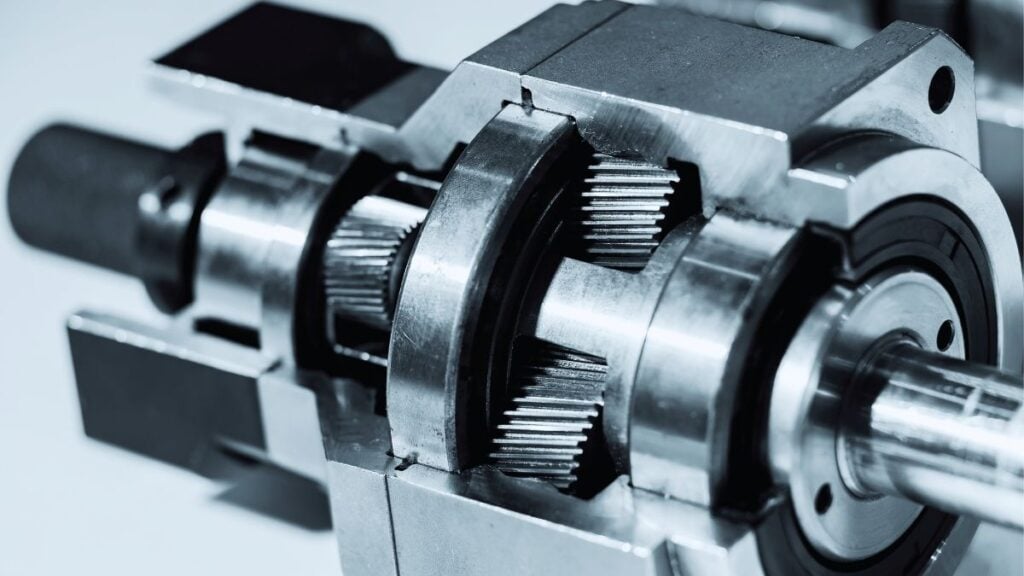

Drivetrain Components

Robotics Gearboxes

Regulated Sub-Assemblies

At a Glance: Advantages vs. Other Processes

If another process is a better fit for cost, weight, or timeline, we’ll

recommend it. You can rely on one partner from prototype to

production with hybrid, additive, and traditional capabilities.

- Tightest practical tolerances and true datums (great for tight-tolerance machining)

- Exotic materials (heat-trained steels and stainless steels,

6061-T651, titanium, and PEEK) - Finish control (machined, bead-blast, anodize, chem film, and

passivation) - Flexibility without tooling (iterate fast and change features

between builds) - Documentation and trust (FAIR/AS9102, CMM reports, and

final inspection for predictable outcomes)

Our Capabilities & Technical Specifications

Milling & Multi-Axis

- 3-axis, 4-axis, and 5-axis (indexed and simultaneous)

- High-speed and hard-metal machining

- Custom fixtures or soft jaws

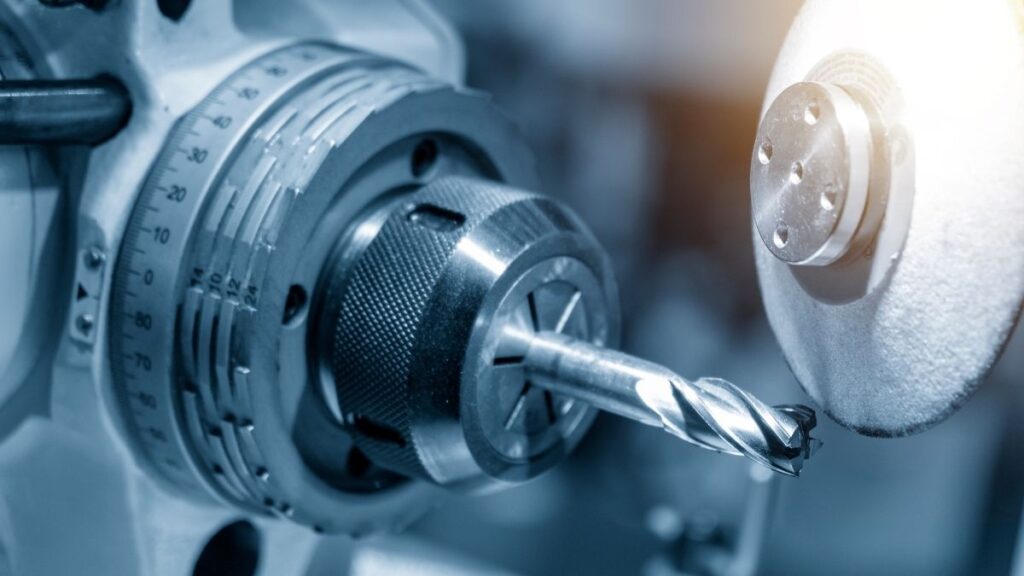

Turning & Mill-Turn

- 2-axis and multi-axis lathes with live tooling

- Y-axis, sub-spindle, bar feed, and chucking

- Swiss-type for ultra-small precision parts

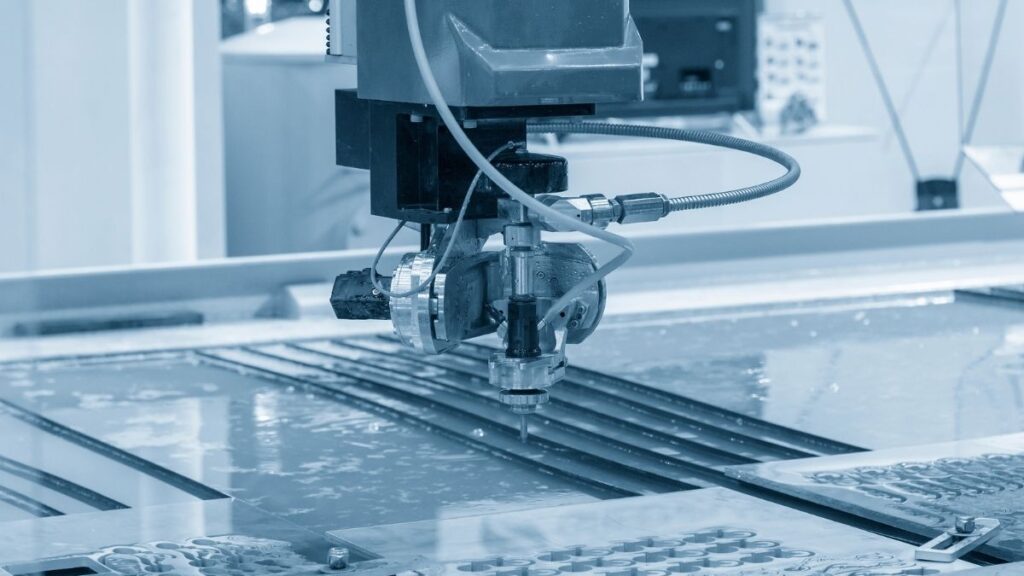

EDM, Grinding, & Specialty

- Wire/sinker/hole-pop EDM

- Surface and cylindrical grinding, and lapping

- Broaching

- Deep-hole drilling

- Reaming and tapping

Cutting & Secondary Processes

- Laser or water jet (as needed)

- Deburr, bead blast, tumble, part marking, assembly, and knitting

Typical Tolerances & GD&T

- Standard: to ±0.005 in (0.127 mm)

- Tight-tolerance machining: ±0.0005 in (12.7 μm) on request (material or geometry dependent)

- GD&T per drawing and UNC/UNF/ISO metric threads

- Inspection: CMM/vision; FAIR/AS9102, PPAP, CPK, Capabilities Study on request

Materials We Offer

Metals

6061/7075/2024/7050 Al

303/304/316/17-4PH SS

1018/4140/4340 steels

Tool steels (A2/D2/O1/S7/H13)

Ti-6Al-4V, Inconel 625/718

Copper, brass, bronze

Magnesium and zinc (on request)

Plastics

Acetal/Delrin (POM)

Nylon (PA)

PEEK

PEI (Ultem)

PTFE

ABS

PC

PMMA

PVC

HDPE

UHMW

G10/FR-4

PPS

PPSU

Finishes & Treatments

Andodize Type II/III (hardcoat)

Chem Film/Chromate

Passivation

Zinc/Tin/Silver/Gold (select apps)

Black Oxide

Powder Coat & Paint

Bead Blast

Laser marking & serialization

Cleanroom packing (as needed)

Heat Treat (solution/aging, quench/temper, case hardening, nitriding)

Quality & Compliance

AS9100 • ISO 9001:2015 • ITAR Registered

We apply rigorous certification standards to every project, ensuring you receive the highest quality products on time, everytime. You can expect your parts to route through A3D headquarters in Phoenix, Arizona, for final QA – no blind dropshipping – so you get predictable outcomes with documentation when needed.

Why this matters to you

- Engineers: tighter control, fewer surprises, faster validation

- Startups: scalable production without new vendor risk

- Supply Chain: traceability, documentation, and consistent delivery from a single accountable partner

Common CNC Machining FAQs

We break down our design guidelines into four main categories below:

- Number of Operations: The location and accessibility of a part’s features will dictate how many setups or

operations are required. Parts with multiple setups may suffer a small tolerance loss between features.

Multiple operations can also affect a project’s cost and lead time. - Reach vs. Width: Long, thin cutters deflect and break. When reaching into a deep pocket, keep the radius

large to accommodate a thicker, more robust cutter. - Internal Stresses: Residual internal stresses in the workpiece, coupled with elevated temperatures

involved in the cutting operation, can cause parts to deflect. This effect is exacerbated when a large

amount of material is being removed from a thin, flat workpiece. - Radii & Tool Access: Rotating cutting tools are essentially cylinders, meaning that internal vertical corners

need a radius, if only a small one. If the cutting tool is unable to reach a feature, it cannot be CNC

machined. Careful tool selection can reach some mild undercuts, but as a general rule, all features should

be in line-of-sight. This effect is exacerbated when a large amount of material is being removed from a

thin, flat workpiece

Due to this process, some visible tool marks may be seen.

If additional finishing is required, please note in your drawings and in your request for quote.

Our finish options are anodized, bead blast, chem film, passivation, and powder coat.

We hold standard to ±0.005” and tight-tolerance machining down to ±0.0005” depending on material or

geometry

Our standard lead time is 14-20 days. We also offer expedited options by request.

Yes, we have AS9100, ISO 9001:2015, and ITAR registered certifications.

Every supplier is vetted and tiered. No blind drop-ship orders and parts are routed through our A3D

Manufacturing headquarters in Phoenix, AZ for final QA.

No minimums. We build 1-1,000+ parts with the same attention to detail, so you can scale how you want and

when you want.

Just simply upload STEP/IGES/Parasolid/SOLIDWORKS type files to request an instant quote.

Every CNC project is reviewed by our manufacturing experts to offer the highest level of review and accuracy

to discuss DFM strategies, process selection, and risk flags