Metal FFF 3D Printing Services

Get strong, functional metal parts and prototypes for use cases like bridge production, part consolidation, customization, and more.

Is Metal FFF Right for Your Part?

How Metal 3D Printing Works

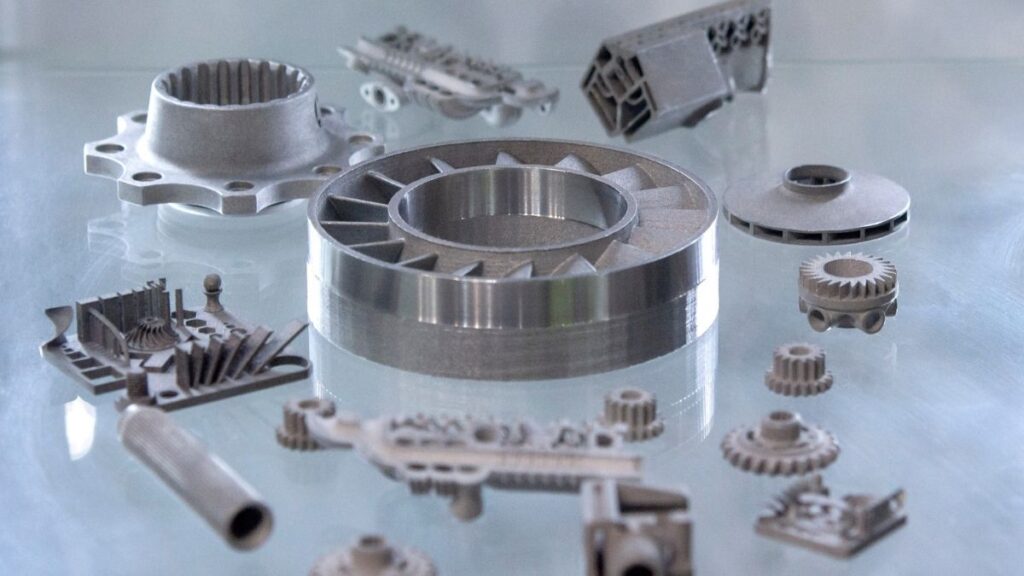

Metal FFF (fused filament fabrication) uses a three-step

process — print → debind (wash) → sinter — to produce solid metal parts from bound metal filament. It’s accessible, cost effective, and ideal for functional metal components with complex designs that are tough to produce through traditional CNC machining.

What Is Metal FFF 3D Printing Ideal For?

- Functional metal prototypes and pilot runs

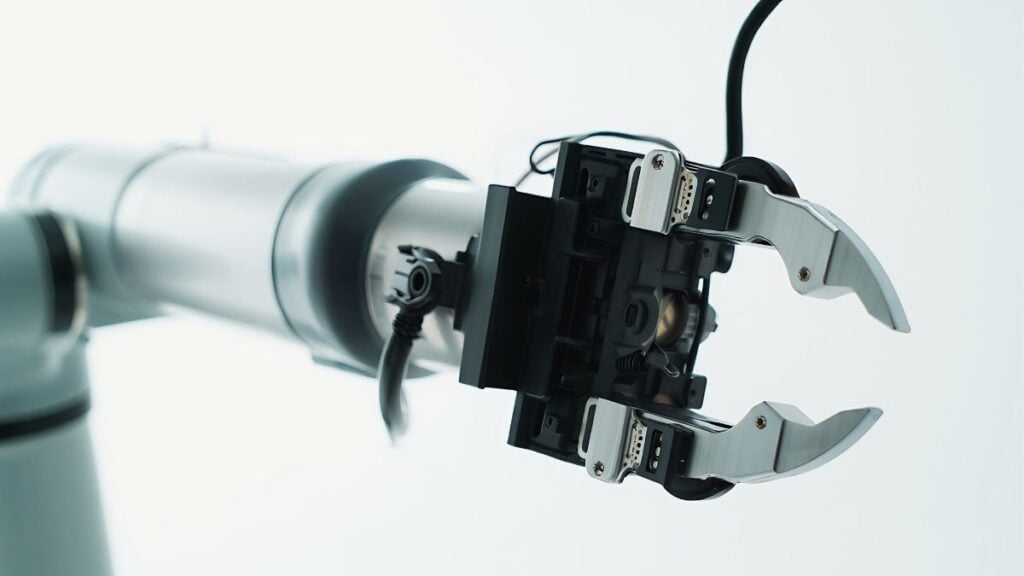

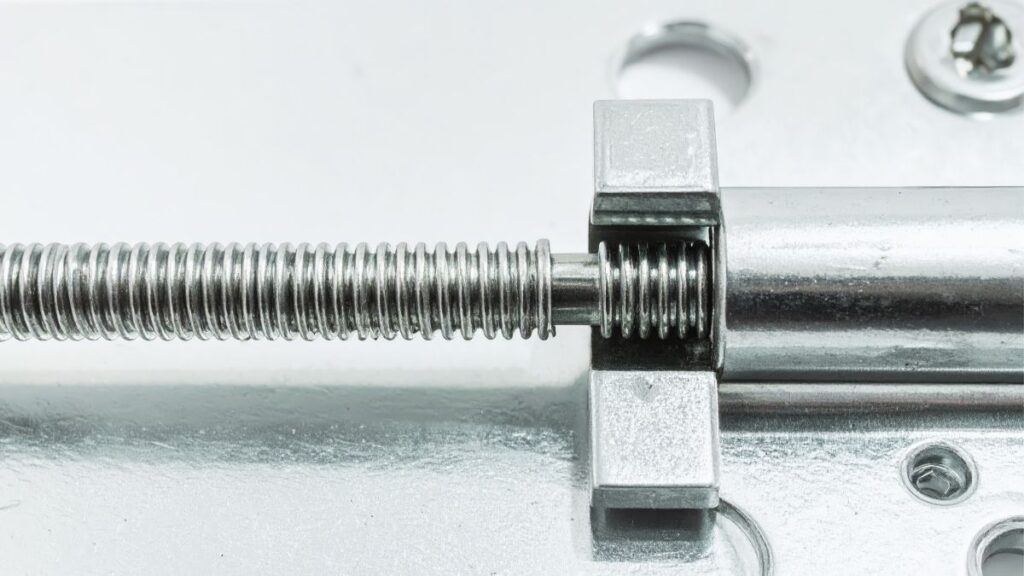

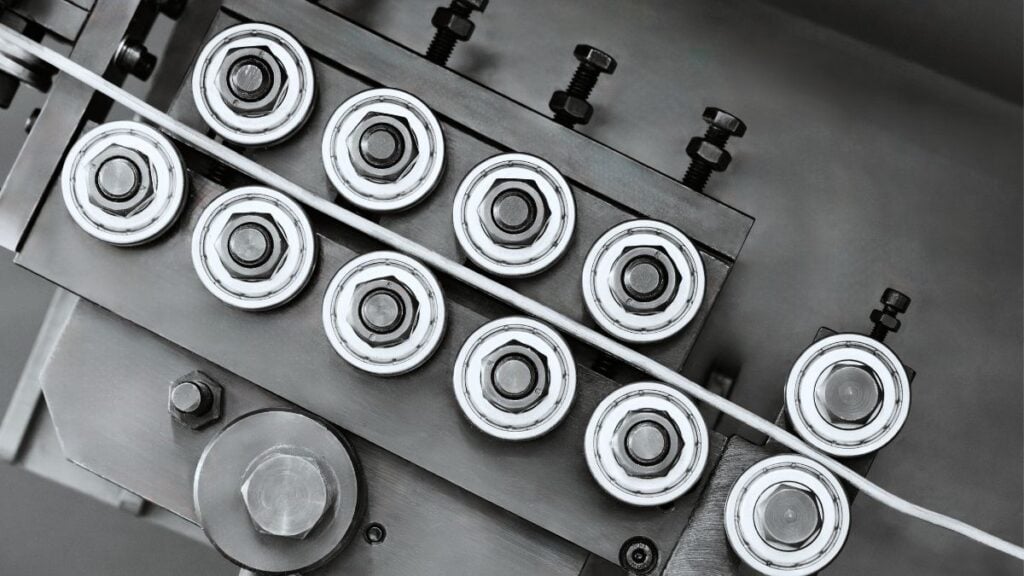

- Fixtures, end-of-arm tooling, manifolds, and high-performance parts

- Hybrid builds (print → machine critical features) for tight functional fits and surface finishes

Common Metal Applications

Gripper Jaws

Actuator Housings

Air-Handling Manifolds

Tooling & Fixtures

Heat Exchangers

Fasteners & Brackets

Metal Prototypes

At a Glance: When to Choose Metal FFF vs. Other Processes

A3D offers application-first guidance. If another process (such as CNC, SLA, SLS, FDM, urethane casting, or sheet metal) will outperform MFJ on cost, weight, or schedule, we’ll recommend it – so you work with one partner from prototype to production.

Comparison

Metal 3D Printing vs. CNC Machining.

Metal 3D Printing vs.

Laser Powder Bed (DMLS/SLM)

Metal 3D Printing vs. Metal Casting

Metal 3D Printing vs.

Polymer 3D Printing (MFJ/SLS/SLA)

Reason

Choose metal FFF when you need more design freedom for difficult geometries while keeping part durability, or when you need to minimize tooling changeover between smaller production

runs.

Choose metal FFF for a simpler, more cost effective approach to prototypes and small batch production.

Choose metal FFF when you need speed to validate designs quickly.

Choose metal FFF when you need real metal properties for heat resistance, strength, durability, and electrical applications where polymers fall short.

Our Capabilities & Technical Specifications

Lead Times

- Standard: about 5 days

- Expedited: available upon request

Available Materials

- 17-4 PH Stainless Steel

- Markforged D2 and H13tool steels

- Inconel 625

- Copper

Layer Thickness

- 50–125 μm (material-dependent)

Build Envelope

- 300 × 220 × 180 mm (X/Y/Z).

Maximum Sinter Envelope

- 235 x 123.3 x 136.5 mm (X/Y/Z)

Maximum Wall

- 1 mm (0.040 in) (material or nozzle dependent)

Part Minimums

- Minimum Wall: 0.040″ (material/nozzle dependent)

- Minumum Feature: 0.020″ (layer-height dependent)

- Minumum Hole:

0.060″ (X/Y)

0.040″ (Z) - Minimum Unsupported Overhang: 45° (50° for Inconel and

copper)

Notes on Density & Structure

- Parts are ~96% dense solid metal

- Interior infill can vary by geometry and intent (solid infill is

possible).

Quality & Compliance

AS9100 • ISO 9001:2015 • ITAR Registered

We apply rigorous certification standards to every project,

ensuring you receive the highest quality products on time, every

time. You can expect your parts to route through A3D

headquarters in Phoenix, Arizona for final QA – no blind drop

shipping – so you get predictable outcomes with documentation

when needed.

Why this matters to you

- Engineers: tighter control, fewer surprises, faster validation

- Startups: scalable production without new vendor risk

- Supply Chain: traceability, documentation, and consistent delivery from a single accountable partner

Common Metal FFF FAQs

Yes, it can be more cost-effective than CNC machining or metal casting if you need rapid prototyping or low

volume production.

Metal 3D printing also gives you more design freedom for complex part geometries while keeping durability, or

when you need to minimize tooling changeover for smaller production runs.

You can upload STEP or STL. We’ll review during quoting to validate if metal FFF is right for you.

Yes, every metal FFF part gets reviewed by an application engineer during the quoting phase to ensure the

part is a good fit for this process.

If there are any modifications that we need to make for the process to work, our team will notify you and help

optimize your design for 3D printing.

Yes, our staff at A3D Manufacturing consists of materials science engineers who are ready to help you

determine the best material for your use case.

Our price correlates to material consumption, print time, wash time, and number of sinter cycles. Infill and layer

height can also affect cost.

Yes, sintered parts are ~96% dense solid metal. Infill strategy may vary by geometry. We also offer solid infill.

Tolerances depend on geometry, size, and material. For critical features, we’ll recommend print-then machine

to hit your functional targets.We’ll flag this during the DFM review.

Yes, post-machining parts is possible. If you have machining requirements that need to be considered after

printing, let us know so we can set up your build and prepare your designs accordingly.