Multi Jet Fusion 3D Printing Services

Get 1 to 1000+ custom production parts and prototypes using HP’s multi jet fusion (MJF) 3D printing technologies.

How MJF 3D Printing Works

Multi jet fusion (MJF) — using HP’s 3D printers — fuses nylon

powder layer-by-layer using infrared energy and fusing and

detailing agents to deliver strong, repeatable parts with fine

feature resolution and excellent surface uniformity.

This method creates isotropic mechanical property parts unique

to 3D printing, giving you powder-bed printing with higher

resolution, smoother surface finish, and superior production

throughput.

Common MJF Applications

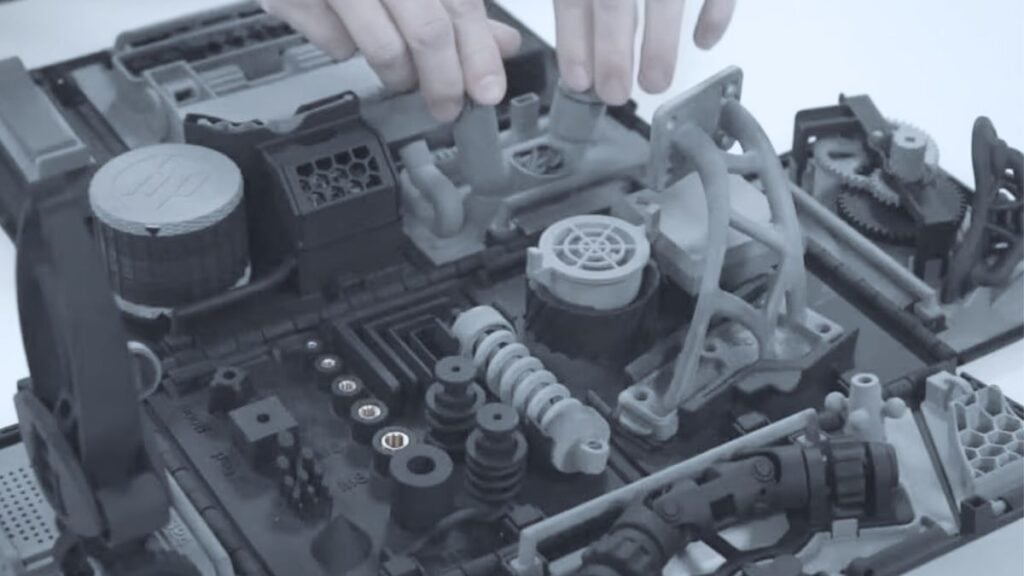

Functional Prototypes

Jigs & Fixtures

Housings & Covers

Ducts & Manifolds

Snap-Fit Clips & Living Hinges

Cable Routing & Brackets

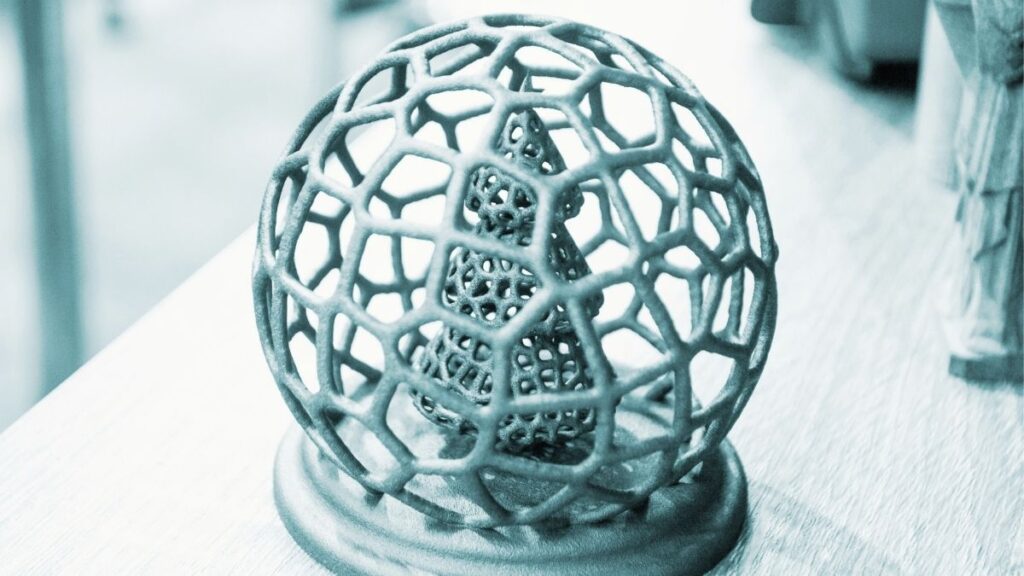

Lattice Structures & Light-Weighting

Test Rigs & Ergonomic Models

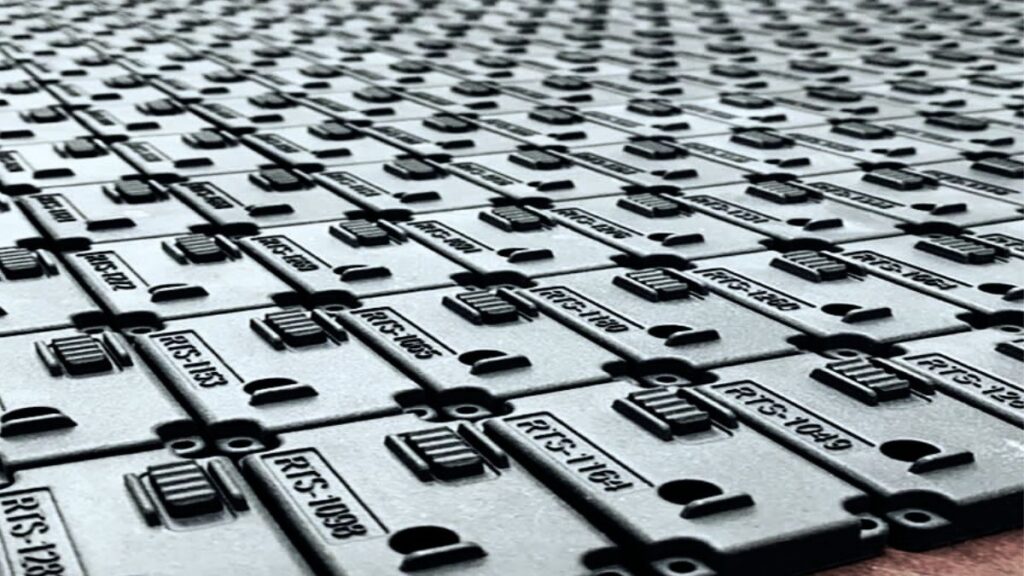

Production Parts

Mass Customization & High-Mix

At a Glance: When to Choose

MJF vs. Other Processes

A3D offers application-first guidance. If another process (such as CNC, SLA, SLS, FDM, urethane casting, or sheet metal) will outperform MFJ on cost, weight, or schedule, we’ll recommend it – so you work with one partner from prototype to production.

Comparison

MJF vs. SLS 3D Printing.

MJF vs. FFF/FDM 3D Printing.

MJF vs. SLA 3D Printing.

MJF vs. CNC Machining.

Reason

MJF typically offers smoother as-printed surfaces and faster turnarounds for production parts.

MJF offers better feature resolution and isotropy. FDM may win on ultra-large builds or

specific materials.

MJF offers functionality, durability, and productivity. SLA wins on ultra-smooth cosmetics and hard and soft tooling masters.

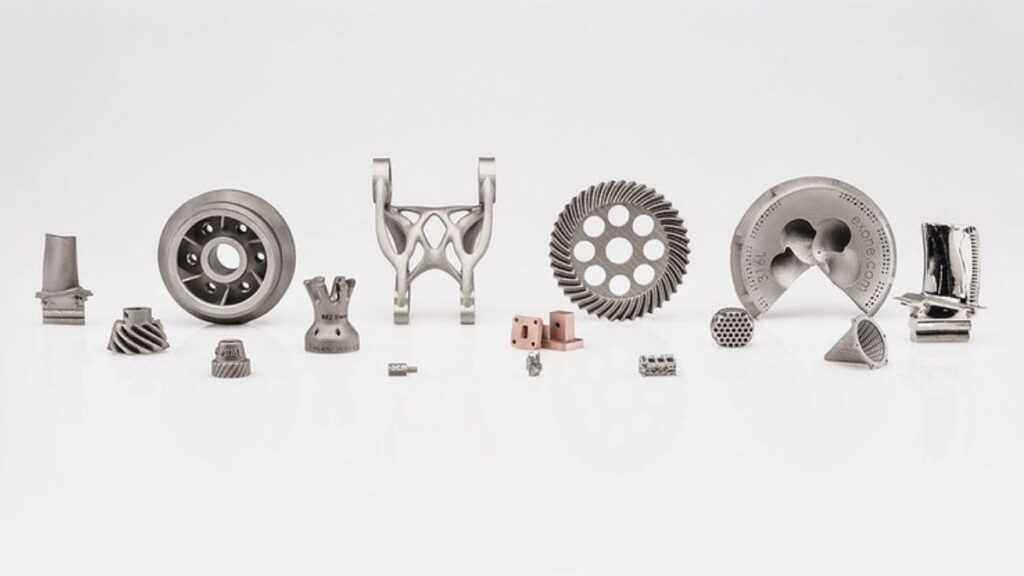

MJF accommodates complex geometries without tooling. CNC wins on metals and tight tolerances.

Our Capabilities & Technical Specifications

Lead Times

- Expedited: Next business day

- Standard: 5-8 business days

Standard Tech Specs

- Standard Accuracy:

- X/Y Direction = +/- 0.012″ or +/- 0.003 in/in, whichever is

greater - Z Direction = +/- 0.020″ or +/- 0.005 in/in, whichever is greater

- Standard Build Layer Thickness: 80 microns

- Maximum Build Volume: 380 x 284 x 380 mm (14.96 x 11.18 x

14.96 in) - Minimum Wall Thickness: 0.030″

- Minimum Clearance for Assemblies: 0.020″

- Minimum Feature Size: 0.030″ (dependent on layer height)

- Minimum Hole Diameter: 0.040″

Material

- Nylon PA 12 – Gray or White: General-purpose strength, good dimensional stability, smooth surface. Great for enclosures, brackets, and fixtures.

- Nylon PA 12 – Full-Color: Cosmetic models and prototypes with labeled features, icons, or color-coded part states.

- Nylon PA 12 – Smooth: Same mechanical properties as PA 12, but with a smoother finish fresh off the printer. Better final finish when coupled with other finishing options.

- Nylon PA 12 – GB (glass bead): Stiffer parts and improved wear resistance. Great for jigs and housings.

- Nylon PA 11: Higher flexibility and impact resistance. Great for living hinges, clips, and snap-fits.

- TPU/TPA: Elastomeric or rubber-like materials. Great for parts like gaskets, grips, and energy absorption.

- Polypropylene (PP): Chemical resistance and flexibility. Great for things like fluid-handling components.

Max Part Size

- 380 x 284 x 380 mm (≈ 15.0 x 11.2 x 15.0 in)

DFM Review

We review geometry, wall thickness, feature size, and orientation to meet functional and cosmetic requirements. Critical features and special instructions available on request.

Finishing

• Bead Blast (standard)

• Bonding

• Inserts

• Mechanical Smoothing

• Vapor Smoothing

• Cerakote

• Standard black dye and premium dye

• Spray Paint

Mechanical/Assembly

• Drill or Tap

• Helicoils

• Tricerts

• Heat-set inserts

• Split and bond of larger parts

Quality Documentation

• FAIR/AS9102

• CMM (coordinate measuring machine) and vision reports

• PPAP (production part approval process) and Cpk (process capability index) as needed

Quality & Compliance

AS9100 • ISO 9001:2015 • ITAR Registered

We apply rigorous certification standards to every project,

ensuring you receive the highest quality products on time, every

time. You can expect your parts to route through A3D

headquarters in Phoenix, Arizona for final QA – no blind drop

shipping – so you get predictable outcomes with documentation

when needed.

Why this matters to you

- Engineers: tighter control, fewer surprises, faster validation

- Startups: scalable production without new vendor risk

- Supply Chain: traceability, documentation, and consistent delivery from a single accountable partner

Common Multi Jet Fusion FAQs

These are our standard accuracy:

- X/Y Direction = +/- 0.012″ or +/- 0.003 in/in, whichever is greater

- Z Direction = +/- 0.020″ or +/- 0.005 in/in, whichever is greater

For critical features, reach out to us for a technical review.

Yes, MJF shines for production parts when you need repeatability, speed, and strong part economics without investing in tooling. Yes, MJF shines for production parts when you need repeatability, speed, and strong part economics without investing in tooling. Yes, MJF shines for production parts when you need repeatability, speed, and strong part economics without investing in tooling.

Yes, we offer PA 12 Full-Color for visual models and TPU/TPA for elastomeric parts.

We offer standard bead blast, mechanical smoothing, vapor smoothing, black dye and premium dye, drill or

tap, inserts, bonding, and select coatings like Cerakote or paint for certain use cases.

Nope, there are no minimums. You can build 1 to 1,000+ parts and scale how and when you want.

Absolutely. Our guidance is application-first and process-agnostic. We’ll recommend MJF, CNC, or a hyrbrid

approach based on performance and risk, not convenience.

Our staff at A3D Manufacturing consists of materials science engineers who are ready to help you determine

the right material for your job. Contact us today to learn more.