Many of today’s top automotive manufacturers and automotive aftermarket suppliers are increasingly choosing hybrid manufacturing options to craft highly custom “can’t get this anywhere” parts and to add scale to normal manufacturing processes.

Hybrid approaches to manufacturing means choosing the right manufacturing technology per part or combining traditional manufacturing like CNC with additive manufacturing for increased strength and/or superior performance. It can also mean scaling with a MaaS (Manufacturing as a Service) provider like A3D Manufacturing, who specialize in both traditional and additive manufacturing technologies.

Breaking Free from Single-Lane Constraints

High-mix, low-volume (HMLV) production and OEM expectations often strain traditional single-process plans, leading to compromises in geometry, tolerances, and costs. Teams get locked into one method, unable to adapt as needs evolve, resulting in delays, retooling, and suboptimal outcomes. A3D’s hybrid manufacturing as a service (MaaS) solves this by offering a flexible, process-agnostic stack that combines the best of traditional and additive technologies, ensuring resilience and efficiency without sacrificing quality.

Defining Hybrid Manufacturing at A3D

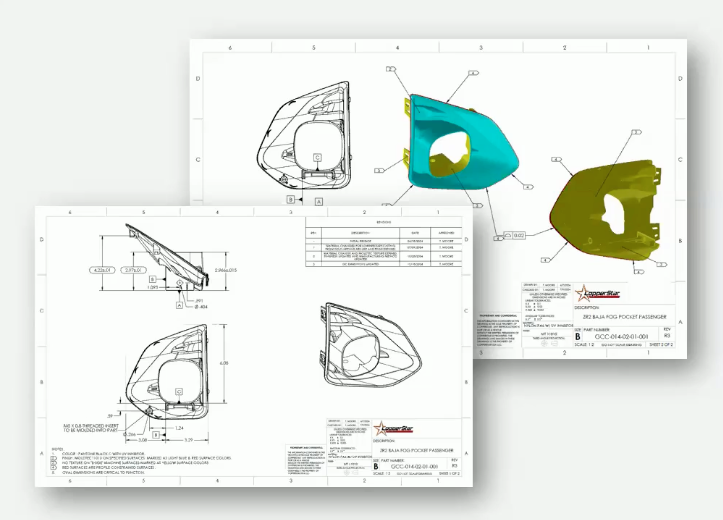

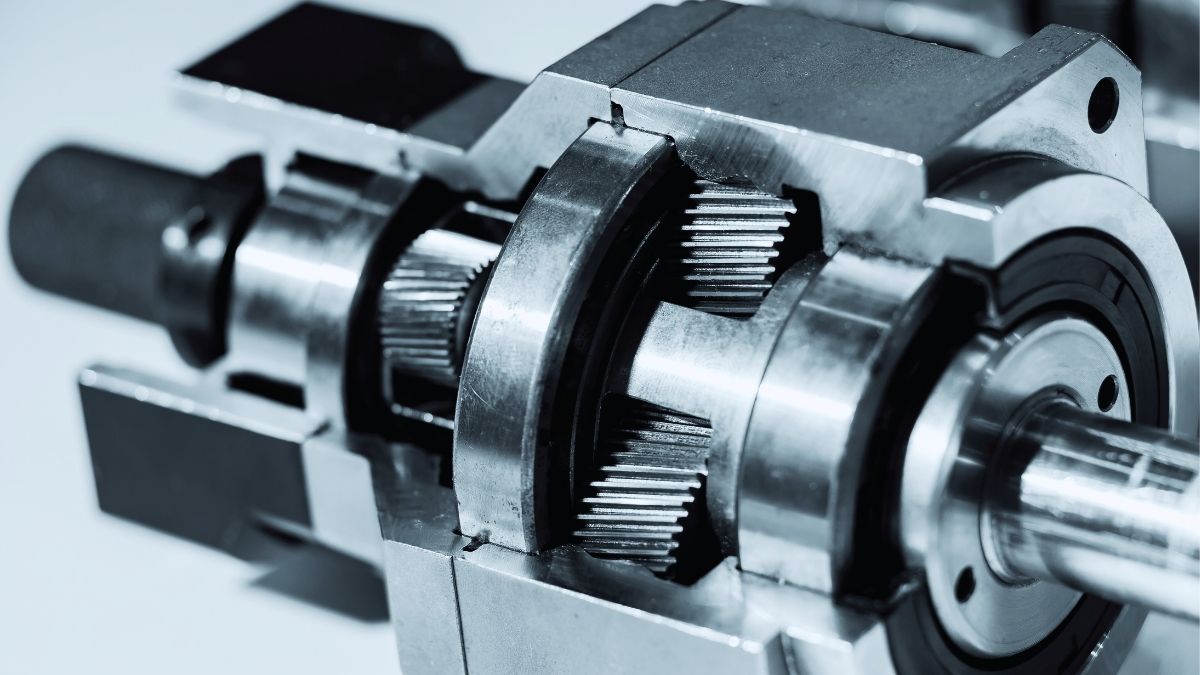

A3D is your Managed MaaS Partner, delivering hybrid solutions across the production lifecycle. This integrates CNC machining, sheet metal fabrication, injection molding, cast urethane, additive manufacturing, and rapid/printed tooling — all routed through one centralized QA and documentation pipeline. Unlike siloed approaches, A3D ensures built-to-spec, traceable parts with enhanced geometry, repeatability, and economics.

Hybrid isn’t about replacing traditional methods: It’s about augmenting them — leveraging additive manufacturing to accelerate phases around CNC, sheet metal, and molding.

5 Ways Hybrid Manufacturing with A3D Unlocks Speed and Precision

- Quality You Can Release: Every order passes through a single pre-ship QA gate at A3D HQ using a stable inspection schema, minimizing lot-to-lot variability and reducing incoming inspection needs. Higher-tier quality controls are available for critical applications.

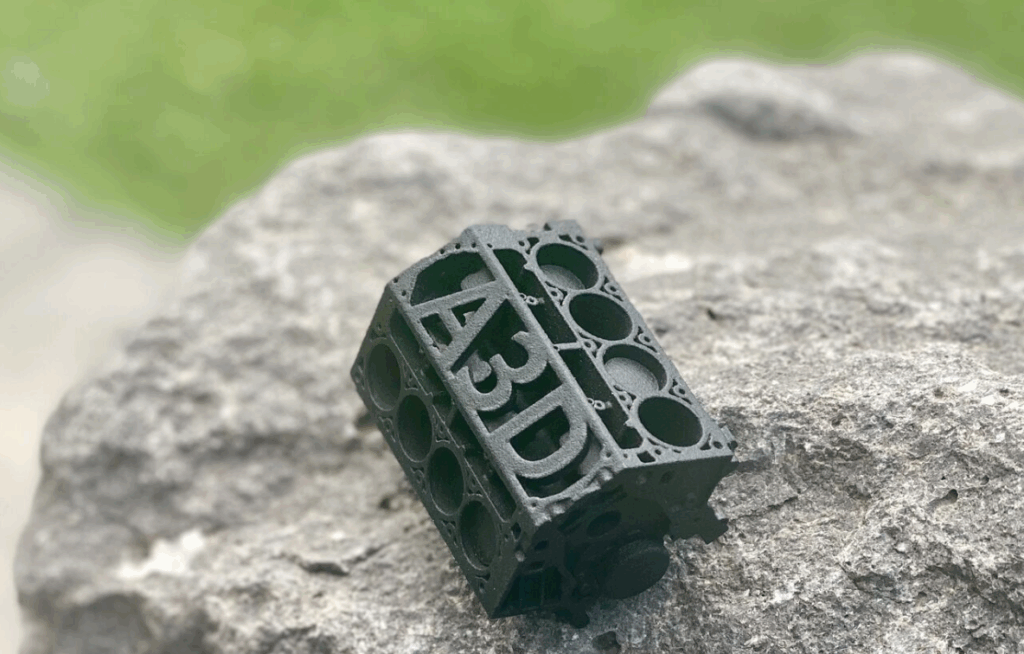

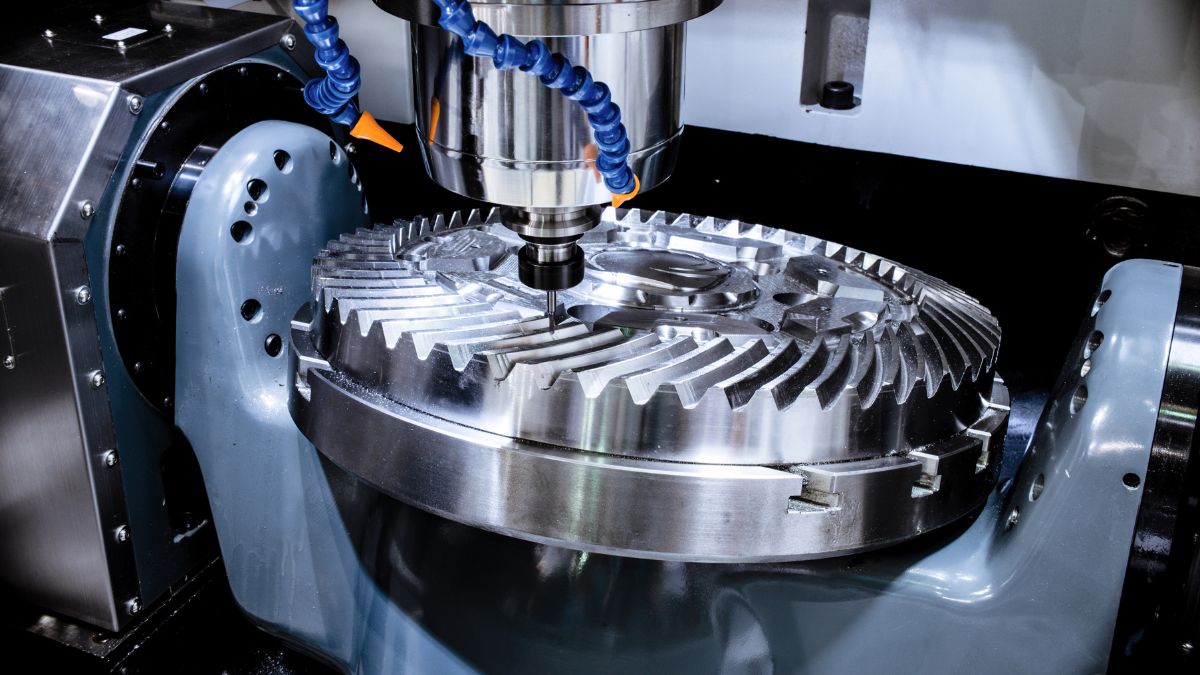

- Capability Unlocks: Hybrid enables what single processes can’t — combining additive manufacturing (AM) for complex geometries (e.g., internal channels or hard-to-reach features) followed by traditional finishing (CNC) to achieve tight tolerances with fewer setups and less scrap.

- Economics & Risk Staging: Match processes to volume and phase; use cast urethane or printed tooling to bridge low volumes, deferring hard-tool investments until validated, saving costs and remaining agile.

- Resilience by Design: Simpler sourcing under one purchase order (PO) allows seamless shifts between AM, traditional, or hybrid paths, keeping programs on track amid product evolution. Additive stop-gap parts can quickly alleviate supply chain interruptions, leading to a de-risked, robust supply chain.

- Frictionless Reorders: Auto-Checkout streamlines new and repeat orders —70%+ of parts are identical to past runs (quantities may vary), or customized like orthotics with pre-set costing for self-service efficiency.

Lifecycle Map: From Exploration to Replenishment

A3D’s hybrid model maps seamlessly to the parts production lifecycle from rapid prototyping all the way to simple replenishment orders:

- Exploration: Rapid prototyping with AM for quick iterations.

- Validation: Cast urethane or AM to test designs without heavy investment.

- Bridge: Hybrid combos (e.g., AM with finishing or post-processing, multi-technology assemblies.)

- Production: Scale with injection molding or sheet metal, optimized for economics.

- Replenishment: Auto-Checkout for fast, identical additive reorders with preserved plans, docs, and inspections.

Lead times naturally shorten through these optimizations, but the focus is on consistent, traceable outcomes.

Practical Plays: Real-World Hybrid Applications

Additive Manufacturing & CNC: Use 3D printing for complex geometries, then CNC for precision finishing.

Split-Lot: Run low-volume portions via AM while ramping up others traditionally.

Printed/Rapid Tooling & Fixtures: Accelerate operations with manufacturing aids like jigs, fixtures, and end-of-arm tooling, unblocking bottlenecks.

Cast Urethane: Bridge to injection molding for validation runs.

Sheet-Metal Substitution: Swap in for cost-effective, durable alternatives in automotive apps.

Customers in the automotive space find the hybrid approach useful for getting their parts created fast with superior geometry:

For example, one of our EV automotive customers, which converts gasoline vehicles to EVs, uses additive manufacturing to 3D print custom dashboard covers with threaded inserts and mounting plates for rare models. For frequently converted models, they shift to urethane casting, molding inserts and mounting to metal plates for robust, volume-friendly production.

See how our customers use manufacturing as a service.

How to Engage with A3D

When you work with A3D Manufacturing, we offer two flexible paths to choose from:

1. Frictionless Auto-Checkout: Ideal for new (instant quote) and repeat orders (custom re-order catalogue) with built-in quality controls — no meetings needed for identical re-orders since all specifications and requirements are saved with each catalogued part.

2. Consultative Production-Lifecycle: For higher stakes, get expert DFM reviews, requirements alignment, and release planning, powered by our full hybrid stack.

Mini Checklist: Know When Hybrid Manufacturing is Right for You

- Tight GD&T requirements

- Complex geometries needing internal features

- Need for bridging low-to-medium volumes

- Strict documentation and traceability demands

- Emphasis on repeatability across runs

Get Started with Hybrid Manufacturing

Ready to optimize your manufacturing? Start with auto-checkout for seamless orders or talk to a manufacturing expert for consultative guidance.

Download our Playbook to learn the five tactics to avoid the most common outsourcing mistakes.