In the dynamic world of 3D printing, expertise is the compass that guides successful outcomes. When it comes to choosing a 3D printing partner for your business, technical know-how can make all the difference between innovation and frustration.

As you evaluate potential 3D printing service partners, consider their track record, client testimonials and the scope of their technical expertise.

Ultimately, a reliable partner will help you harness the full potential of 3D printing technology, positioning your business for innovation and growth.

We’ll delve into the top five factors of 3D printing expertise that address the importance of working with a partner who understands the technology and comprehends the unique needs of your industry.

1. The Power of Technical Expertise

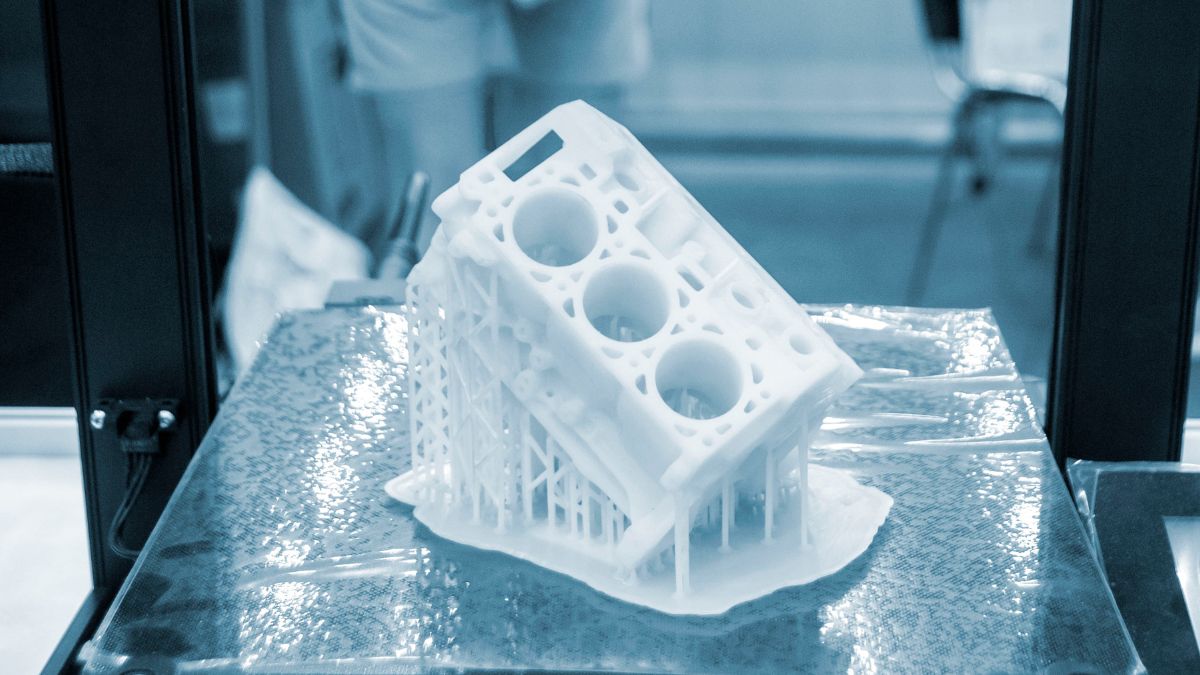

3D printing technology is a universe in itself, with many processes, materials and design considerations.

A true 3D printing partner possesses in-depth technical expertise, having navigated the complexities of various 3D printing methods.

These are the four most used 3D printing methods:

- Multi-jet fusion (MJF)

- Fused deposition modeling (FDM)/Fused filament fabrication (FFF)

- Stereolithography (SLA)

- Selective laser sintering (SLS)

A service partner who knows various 3D printing methods can guide you better in selecting the most suitable 3D printing technique for your project, and you can be confident that they will maximize your outcomes in a cost-effective way.

2. Know the Type of Materials You Need and Design Challenges

Selecting the right material is an important decision that directly impacts the functionality and durability of your 3D-printed parts.

An experienced partner offers diverse materials and advises on their unique properties and applications.

Whether your project requires high-temperature resistance, biocompatibility or mechanical strength, your partner’s technical know-how ensures the selection of materials aligned with your requirements.

Additionally, your 3D printing partner assists in optimizing your designs for manufacturability and enhances your parts’ quality and performance.

3. Possess the Skills to Overcome Your Unique Complexities and Pitfalls

3D printing can have challenges such as layer adhesion issues, warping and distortion.

A proficient partner anticipates and mitigates these challenges and uses their technical know-how to implement solutions that yield successful prints.

With a deep understanding of slicing parameters, build orientation and post-processing techniques, they navigate these complexities with precision, minimizing rework and wastage.

4. Ensuring Quality Control at Every Stage

Quality control is often the backbone of any successful 3D printing and manufacturing project. A reliable partner employs stringent quality assurance processes at every stage of production.

From raw material inspection to in-process monitoring and post-production testing, your partner’s technical expertise ensures that each part meets the desired specifications. Their attention to quality guarantees consistency and reliability in your 3D-printed components.

A proficient partner maintains a high-quality standard by maintaining a quality management system (QMS) and auditing their own internal processes for compliance with specific standards, such as ISO 9001:2015.

Not all service providers maintain the same quality standards or systems, leading to inconsistencies, unexpected challenges and subpar results in your 3D printing projects.

Choosing a partner who prioritizes rigorous quality control measures ensures that your parts meet the highest performance, durability and functionality standards.

5. Supporting You from Prototype to Production

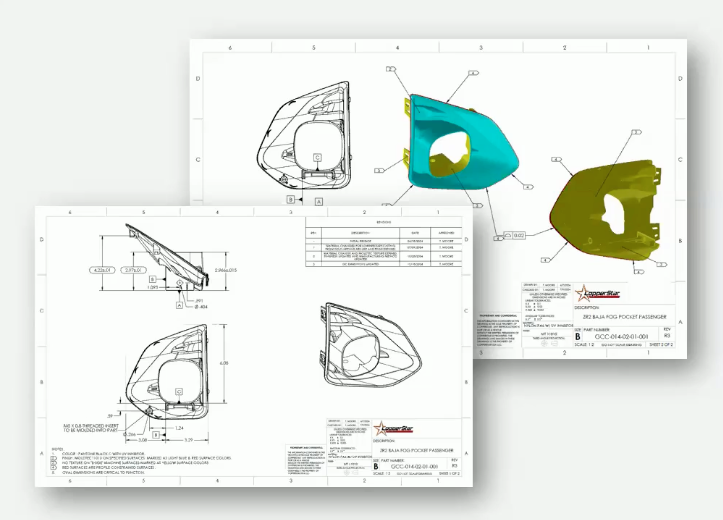

Your journey from prototype to production requires a seamless transition that only technical expertise can facilitate.

An adept partner supports you through the entire lifecycle, ensuring your prototypes evolve into production-grade parts without compromising quality or integrity.

Your expert 3D printing partner should have insights into part consolidation, batch printing and scaling, allowing for cost-efficient production while maintaining consistency and performance.

How A3D Manufacturing Goes Beyond for Your 3D Printing Needs

By choosing a 3D printing partner with robust technical know-how, you’re investing in a partnership that transcends technology, delivering tangible value and transformative solutions.

With our unwavering commitment to maintaining exceptional quality through robust quality management systems, we stand as a beacon of reliability in 3D printing services.

At A3D Manufacturing, we go beyond providing 3D printing services. We understand that businesses have diverse needs and goals, and we are here to help you achieve them.

Our commitment extends to offering various solutions that cater to your preferences.

Aside from our capabilities to provide high-quality products within a quick turnaround, here are a couple of additional avenues why our customers choose us:

- Offload Production Work: Some customers look to offload production work to focus on their core competencies. If that’s the case for you, our experienced team is ready to take on the responsibility.

- Add 3D Printers In-House: Other customers consider bringing 3D printers in-house to enhance their capabilities. We can seamlessly transition the production to your internal manufacturing team.

These two types of support give our customers flexibility and reflect our dedication to meeting their goals.

So, whether you collaborate with us for production or embark on an in-house 3D printing journey, we’re here for you.

Contact us today to embark on a journey of innovation and unmatched quality.