New tariffs are affecting everyone, but that’s not stopping American manufacturers.

Companies like Nvidia and Honda recently announced plans to continue to invest heavily in US-sourced manufacturing. Potential layoffs and price increases on materials are likely, but machine shops and manufacturing providers still have options to offset some of the fallout from these issues.

They can buy locally. Swap out materials. Use different suppliers and methods. And with that, they can become part of the revitalization of the US manufacturing sector, significantly contributing to economic prosperity at the national level.

1. Nearshoring with American-Made Manufacturing Service Providers

Tariffs are a headache, but knowing your part or product is 100% made in America? Priceless. It also:

- Matches consumer preference to buy American

- Ensures better traceability

- Reduces carbon emissions from shipping and transportation costs

Using manufacturing-as-a-service (MaaS) providers, like A3D Manufacturing, means you can pick up the phone and talk directly to the people involved in bringing your ideas to life, get the right consultation and advice on material selection, manufacturing method, and more.

MaaS with A3D Manufacturing means you can get high-quality manufacturing services like CNC machining, injection molding, sheet metal, 3D printing, and more on-demand.

If you want to cut down on lead times, save money, and help the resurgence of American manufacturing, who you choose to do business with matters. We are proud to be:

- Locally based in Arizona, United States.

- Deeply connected to an extensive network of manufacturers, suppliers, and businesses in North America.

- Industry certified and partnered (ISO 9001, AS9100, ITAR-compliant, HP Certified Partner).

2. Making Your Part with the Right Materials: Aluminum or Carbon Fiber?

At A3D Manufacturing, we not only help you choose the right type of manufacturing for your part or prototype, we also advise on which materials will best suite your application. We work with upwards of 100 unique materials and have produced over 200,000 different parts.

With the recent tariffs on aluminum and steel, manufacturers may need to look at diversifying the materials they work with.

Does your part really need to be made with a specific material, or are there alternatives that you should consider?

For example, you can’t use carbon fiber for everything. You’ll want to use aluminum for heat sinks and electrical enclosures with ESD or shielding requirements ¾ it’s high electrical conductivity, stability, and heat resistance make it the ideal material for a lot of applications.

But if your part doesn’t need those requirements met and you’re looking for high strength ¾ and say, there’s a shortage of aluminum or something like that (not that that has ever happened) ¾ consider alternative materials like composites.

You can produce parts with strength that contend with aluminum by using carbon fiber filled plastics.

The key to unlocking “aluminum strength” parts through 3D printing is in understanding the stresses the part will see and reinforcing with fibers in a way that addresses those stresses.

A fantastic example of this: Mounting plates.

They need to be stiff and resist flexure. You can 3D print mounting plates that are super strong with reinforced carbon fiber by using a layout that follows composite sandwich panel design guidelines ¾ two thin layers towards the top and bottom of the part.

Other good applications for high-strength carbon fiber parts include things like complex brackets with carbon fibers that reinforce the part in all the right locations and directions so it’s resistant to tensile, flexural, or hoop stresses the part will experience during use.

Getting a Part with A3D Manufacturing: Self-Service Online

With our manufacturing services, you can simply upload your part and get a quote.

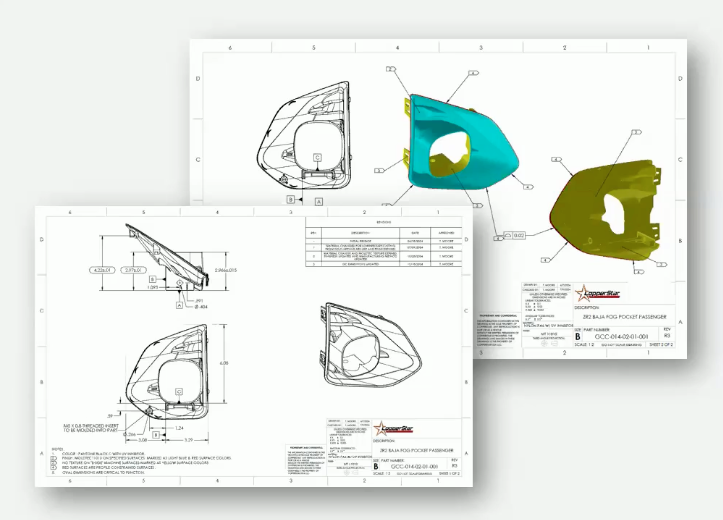

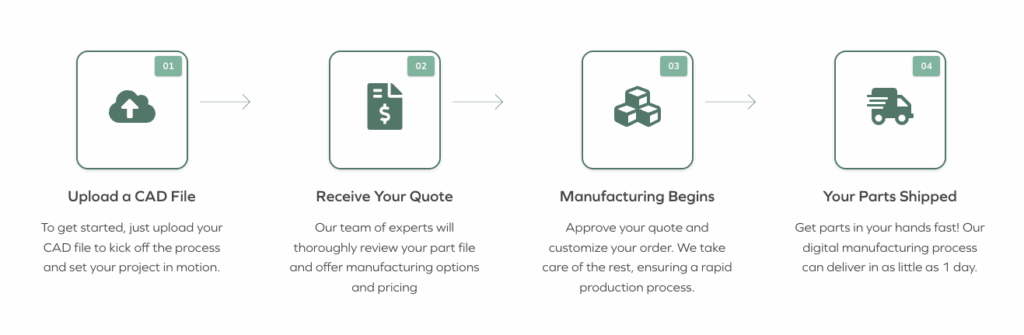

It’s simple to get a part made with A3D Manufacturing. Here’s how it’s done in four easy steps:

1. Upload your CAD file: We accept over 40+ different file types for upload. Tell us any special requests or additional information about your project, and if you need delivery by a specific date.

2. Approve Quote: You then receive the quote from our experts after we’ve reviewed your part file and project details.

3. Manufacturing: You can approve your quote and customize your order. We start making it.

4. Delivery: We ship your parts in days, not weeks.

On-Demand North American Manufacturing: Committing to Made in America

If you’re a manufacturer in the United States, it can be difficult to find the right manufacturing services, tools, and expertise you need locally. With A3D Manufacturing solutions, you can optimize your manufacturing workflows, get parts fast, and lower operational costs. Give us a call or try out our online service for manufactured parts on demand.