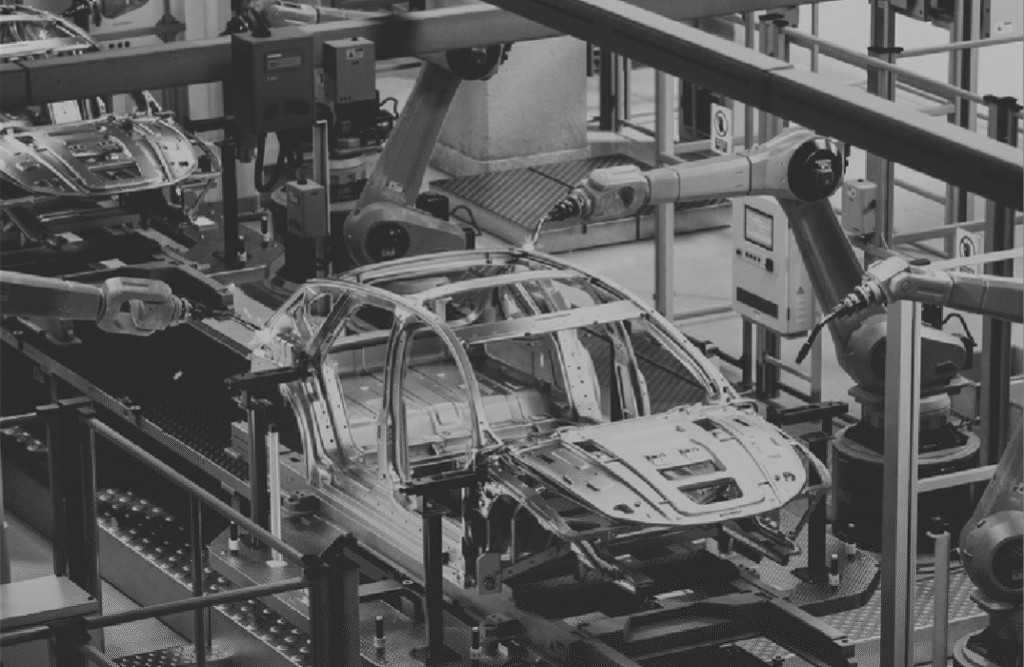

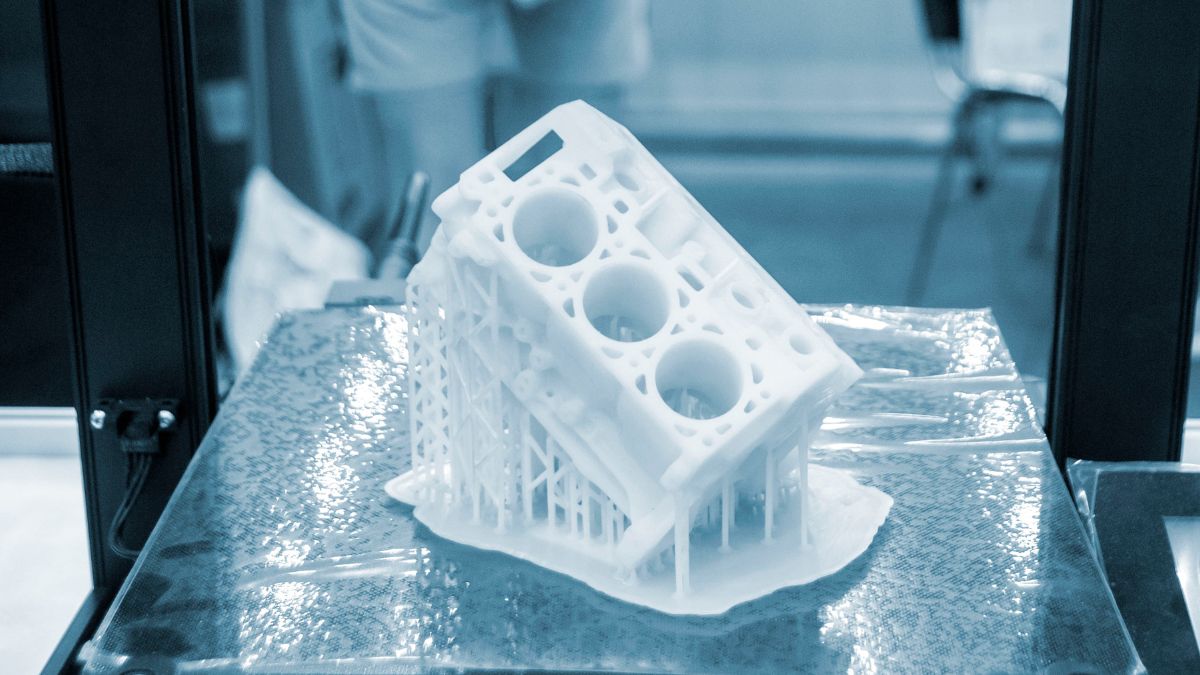

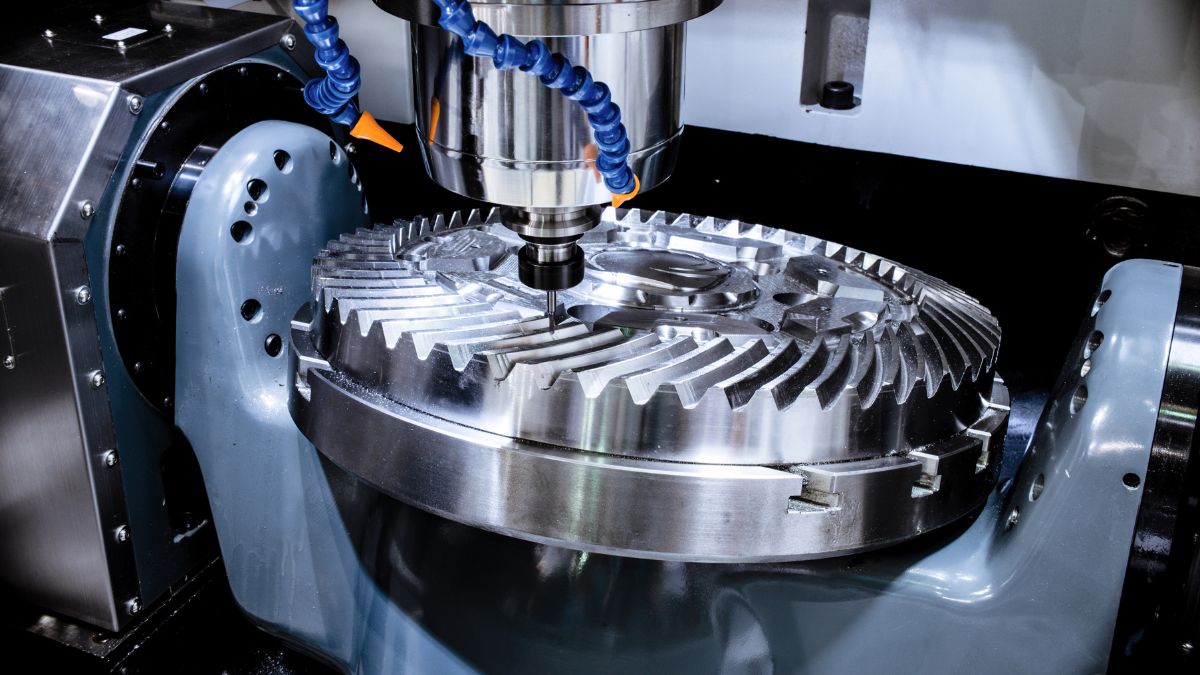

Manufacturing as a service in the automotive sector can be a tremendous value-add. You can craft custom “can’t-get-this-anywhere” parts with modern additive manufacturing, CNC, injection molding, and more. Think on-demand production of obsolete parts for classic cars or enhancing and adding customization to an OEM (Original Equipment Manufacturer) part.

With MaaS (Manufacturing as a Service), there’s no capital investment, meaning this is also an excellent way to get a prototype made or to scale a part for production. Outsourcing manufacturing gives benefits like cost savings and scalability, but introduces some caveats as well.

The top five roadblocks with outsourcing parts:

- Black Box Vendors

- Inaccurate Quotes

- Bad Handoff

- Wrong Scope

- Lack of Documentation

Black Box Vendors

Black box vendors are known for vague contracts, lack of quality control, not providing information about exactly where your part was made, who made it, when it’s getting crafted, shipped, and inspected.

Good manufacturing suppliers use contracts and quality management to make sure you get exactly what you’re expecting. You’ll know exactly where your part was made, who made it, and when it’s getting crafted, shipped, and inspected. They’ll provide an NDA, relevant links and information, and keep the lines of communication open. In other words, they’ll be transparent and communicative in every interaction.

Inaccurate Quotes

Some vendors will trim auxiliary steps and process in the initial scoping to appear more competitive. Unforeseen costs come later.

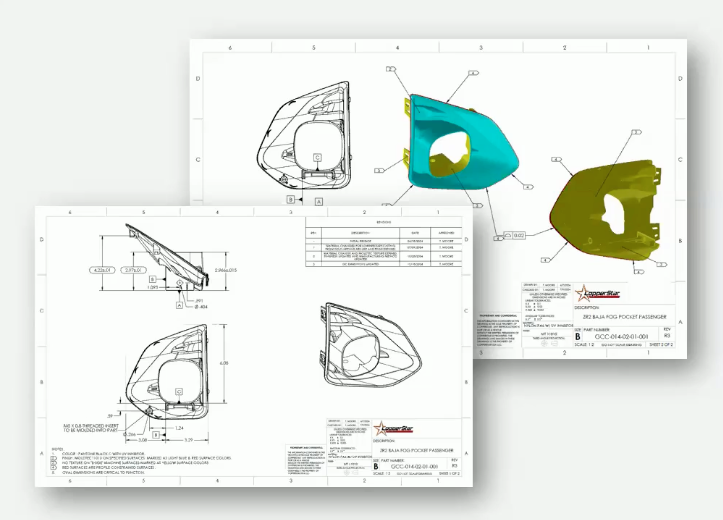

A good manufacturing vendor will start with application-first guidance (which will influence overall costs) and provide alternatives to hit the specifications on time and in budget. They’ll provide timely quotes, get your DFM (Design for Manufacturing) reviewed by actual manufacturing experts, and help alleviate any and all assumptions about materials, finishes, and tolerances. Risks are noted and communicated up front.

Bad Handoff

Not all manufacturing vendors have a good quality management system in place. If information about who inspected the batch is missing, this is a red flag.

Companies that are ISO (International Organization for Standardization) certified or have gone the extra mile to ensure accreditation are a good indicator that their quality control process is consistent and high quality. A good manufacturing partner uses a standard inspection schema every time (which includes agreed critical dimensions, method, sample size, acceptance criteria, and a standard release pack.)

Wrong Scope

Some vendors will try to apply a one-size fits all approach. The quoted processes might not fit the DFM of the part, intended performance, or desired final aesthetics. What may seem quick and simple now, potentially leads to inefficiencies when scaling production, or a poor performing part.

A good manufacturing vendor partner will have spec sheets detailing all available technologies, capabilities, and materials readily available for download on their website.

Their recommendations will include process-agnostic planning and pre-approved alternates (AM, CNC, Sheet Metal, Cast Urethane/rapid tooling, or hybrid), so parts are made by the right method for spec, volume, and cost (not just by whatever machine is available).

Lack of Documentation & Certifications

If you’re not getting detailed inspection reports, supporting documents, revision history, and traceability information from your manufacturing partner, then does that information even exist on their side? Some companies don’t have a reliable way of capturing and sharing this data. For compliance reasons, this is simply unacceptable.

A good manufacturing vendor provides a certified quality system that supports documentation and traceability. You’ll get access to tools and information like revision history, build travelers that track each step down to the date and technician, and they’ll have MES (Manufacturing Execution System) programs that track production progress. Deliverables include material certifications, certificates of compliance, inspection reports, and detailed part labels that include lot numbers.

Meet Your MaaS Partner: A3D Manufacturing

Things to consider when sourcing a manufacturing partner: Do you need parts quickly and just want to upload your part and get a quote now? Or do you need a more consultative approach to dig deep into the details, materials, and methods before choosing a solution?

A3D offers two paths to get your part made to spec:

- Auto-Checkout: Fast, self-serve directly from the website for new orders and replenishment (same plan, same docs). No meetings are needed for identical or similar parts made with additive technologies. Auto-checkout doesn’t come with valuable expert reviews and feedback, like the consultative lifecycle approach.

- Consultative Lifecycle: Great for additive projects, though most traditional technologies require more in-depth review. Instantly compare numerous processes, materials, finishes, even lead times, without having to formally ask for 12 different quote scenarios. Is your project in the recurring re-order phase? Ask A3D to generate a catalogue for quick and easy replenishment and capture every detail/requirement.

Either way, you get timely quotes, quality assurance, and complete traceability every time. Don’t let outsourcing roadblocks slow you down.

Get your high-quality automotive parts built fast, the first time. Get a quote now or talk to an Expert at A3D Manufacturing today.