What Is Hybrid Manufacturing? A Strategy, Not a Technology

Hybrid manufacturing is a strategy rather than a single technology. It involves integrating additive manufacturing (like 3D printing) with subtractive or traditional methods (such as CNC machining, injection molding, or urethane casting) to optimize the entire product lifecycle.

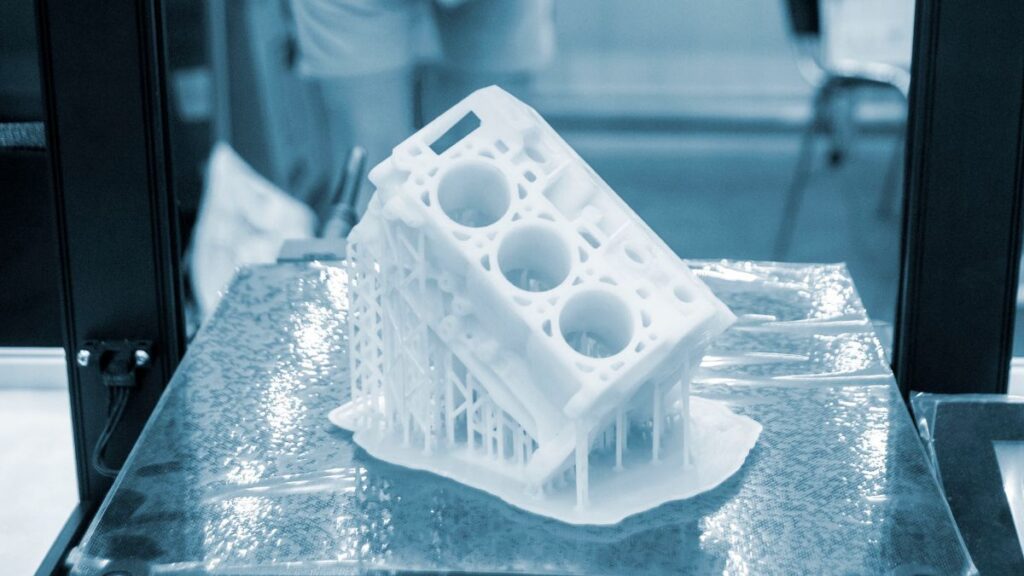

In a classic hybrid flow, you might start with 3D printing for rapid prototyping, transition to urethane casting for low-volume bridge production and scale up to injection molding for high-volume runs. However, it’s not always linear. Some components might remain additive throughout due to complex geometries or customization needs, while others shift to CNC for tight tolerances.

The key is choosing the right process at the right time for the right product. This requires evaluating variables like customer needs, business profitability, and supply chain constraints early in the design phase.

Hybrid isn’t about dropping traditional manufacturing methods and soley relying on 3D printing – it’s about combining the strengths of multiple types of manufacturing methods to get the lowest cost, highest quality part with the right materials and finishes.

As an example, 3D printing might handle intricate internal features in a fluid manifold, while CNC finishes mating surfaces for precision assembly.

Pros and Cons: The Realities of Hybrid Manufacturing

No single approach to manufacturing is perfect. Here are some of the advantages and challenges of hybrid manufacturing:

Pros:

- Reduced Lead Times: Hybrid fills gaps in traditional processes. You can use 3D printing to prototype quickly while tooling is developed, avoiding delays

- Complex Geometries and Performance Gains: Additive excels at lightweighting (removing unnecessary material), part consolidation (creating monolithic designs to reduce assembly and leaks), and internal features (like fluid channels) that are impossible or costly with machining

- Lower Tooling Costs: You can skip expensive molds for low volumes with 3D printing or urethane casting, which has minimal upfront investment

- Quick Design Changes: You can incorporate user feedback mid-production without retooling, enabling agility in a feedback-driven market

Cons (or Considerations):

- Technology Overload: Bringing all processes in-house (additive, subtractive, molding) is unrealistic for most — requiring massive investment in equipment, materials, and expertise

- Coordination Challenges: Managing multiple workflows simultaneously can be complex

- Learning Curve: Engineers must master design for manufacturing (DFM) for each technology to ensure efficiency

- Expertise Required: Knowing each method’s strengths and limitations demands specialists and pivoting between them isn’t intuitive

Using services from A3D gives businesses access to a “smorgasbord” of technologies without the overhead.

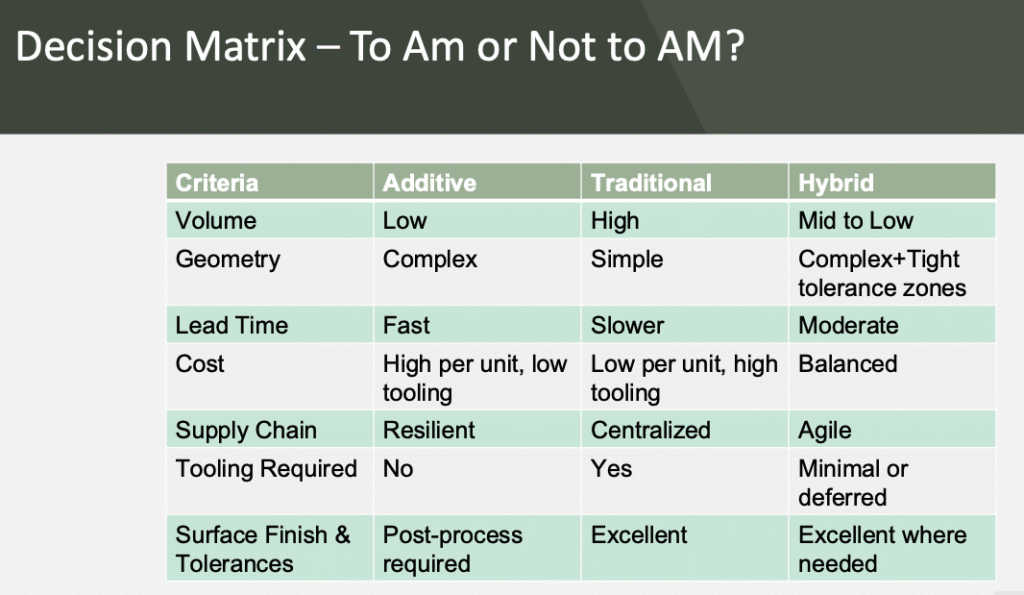

When to Print vs. When to Machine: A Decision Framework

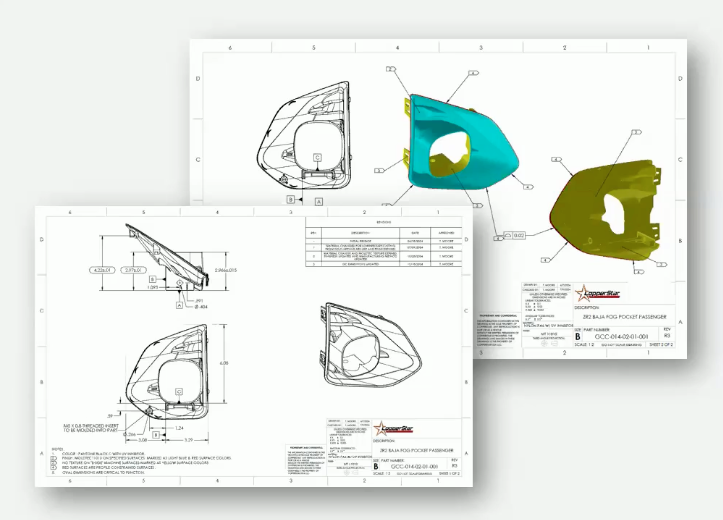

A3D Manufacturing recommends using a matrix for evaluation, factoring in quantity, complexity, tolerances, materials, and lifecycle stage. Here are some general criteria for deciding when to print versus when to machine. If you’re still not sure, A3D will work with you to determine the best option for your build.

When to 3D Print:

- Prototyping and Iteration: Always print first. It’s fast, allows quick changes, and lets you test minimum viable products without perfect DFM

- Demo Units and User Testing: Get feedback by producing small batches (e.g., 10 units) for field trials

- Manufacturing Aids: Jigs, fixtures, and guides are ideal for additive — customizable and cost-effective

- Performance Enhancements: Lightweighting, complex/internal geometries, and part consolidation shine here

- High-Mix or Customization: For configurable products or mass personalization, additive’s flexibility beats tooling-heavy methods

- General Rule: Smaller, feature-rich parts at lower volumes (hundreds to thousands) are prime candidates

“The more complex and smaller the part, the better for 3D printing in production.”

-Michael Dymond, Product Manager at A3D Manufacturing

When to Machine (or Use Traditional Methods):

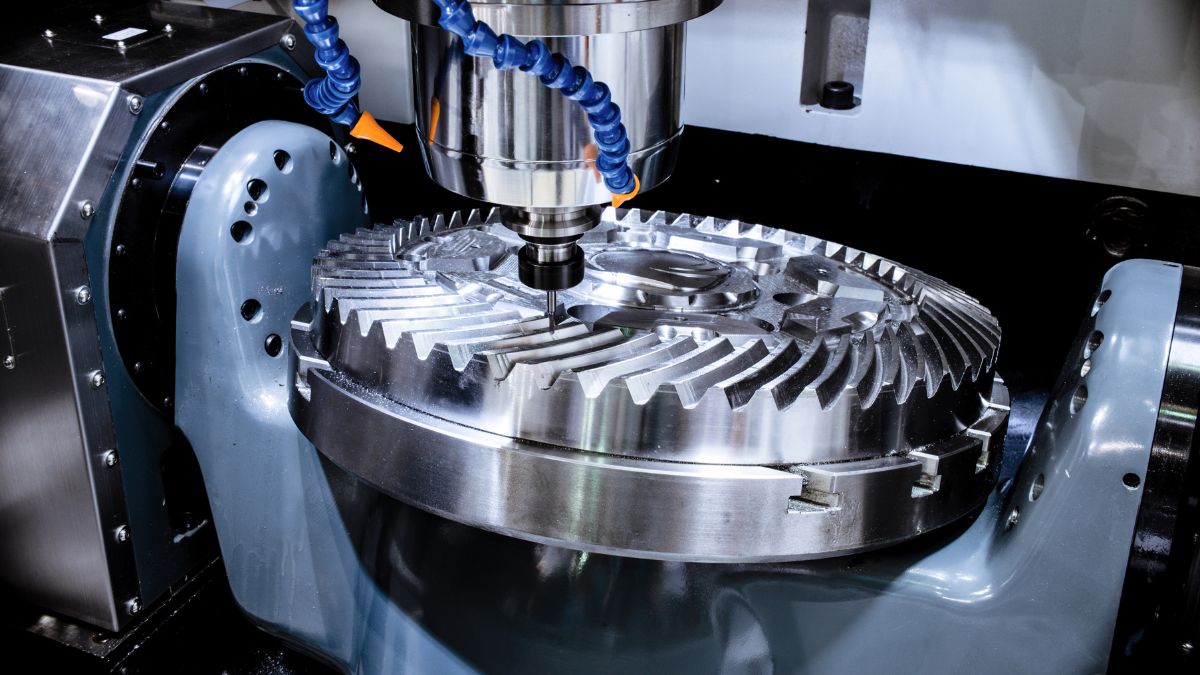

- Tight Tolerances: CNC delivers precision down to 0.0001 inches — unmatched by most additive processes

- High-Performance Materials: Access diverse options like thermal/chemical-resistant plastics (e.g., Delrin, HDPE) or custom alloys not available in 3D printing

- Material Evaluation: Prototype with exact end-use materials that additive can’t replicate

- Legacy Parts: Many components have been machined for decades. Reevaluate periodically (some will stay traditional)

- High Volumes: At scale, traditional methods like injection molding offer lower unit costs despite high tooling

Mass customization is not advisable with traditional manufacturing alone, while lightweighting with generative design often demands additive.

Real-World Use Cases from A3D Customers: Hybrid Manufacturing in Action

Interlink Engineering

Interlink used A3D’s hybrid approach to move from prototype to production faster without sacrificing quality. Even without a large budget, Interlink was able to progress through production steps using the most appropriate manufacturing methods at each stage.

Other A3D Customer’s use hybrid manufacturing for things like:

- Medical Devices: Use Multi Jet Fusion (MJF) for bridge production during year-long validations, conceding on gloss for speed

- Aerospace Components: 3D print complex manifolds for fluid management, then CNC mate surfaces

- Consumer Products: Iterate enclosures with additive for user feedback, then mold for scale

- Automotive: Lightweight brackets via generative design in additive, while machining high-wear parts

Another Standout: One company used hybrid to soft-launch, building market share before full tooling investment.

The Design-to-Production Lifecycle for Hybrid

Example hybrid workflow for a specific product’s journey:

- Prototyping: 3D print for speed and iteration; higher unit costs but no NRE (Non Recurring Engineering)

- Bridge Production: Urethane casting for awkward quantities (10-50); low tooling, moderate costs, but some concessions (e.g., no perfect draft)

- Production: Injection molding for high volumes; unlocks materials and precision, justified by scale

- End-of-Life: Circle back to additive for spare parts or upgrades, extending product life without molds

Bonus: Upgrading field products with 3D-printed iterations can create new revenue streams and keep customers happy.

Q&A Hybrid Manufacturing

When Should I Avoid Additive or Traditional? Avoid additive for tons of small metal parts (better for CNC) or large simple enclosures (use sheet metal). Traditional can’t handle mass customization.

When Should I Consider In-House Hybrid Manufacturing/Investment in Tooling? Use cost-benefit analysis and demand projections; switch earlier if performance gains (e.g., aesthetics) matter.

How Do I Select the Right Materials? Build a matrix covering mechanical, aesthetic, environmental, and compliance needs. Work with a manufacturing partner who has trained material specialists in-house like A3D for specific guidance on material selection.

Embrace Hybrid for a Competitive Edge

Hybrid manufacturing isn’t a buzzword — it’s a powerhouse strategy for navigating modern demands. Success lies in early planning, expert guidance, and flexibility. By blending additive’s innovation with traditional’s robustness, manufacturers can reduce risks, boost efficiency, and delight customers.

If you’re exploring hybrid options, start with a decision matrix and consult specialists at A3D Manufacturing.