Interlink Engineering and A3D Manufacturing: Partners in Production

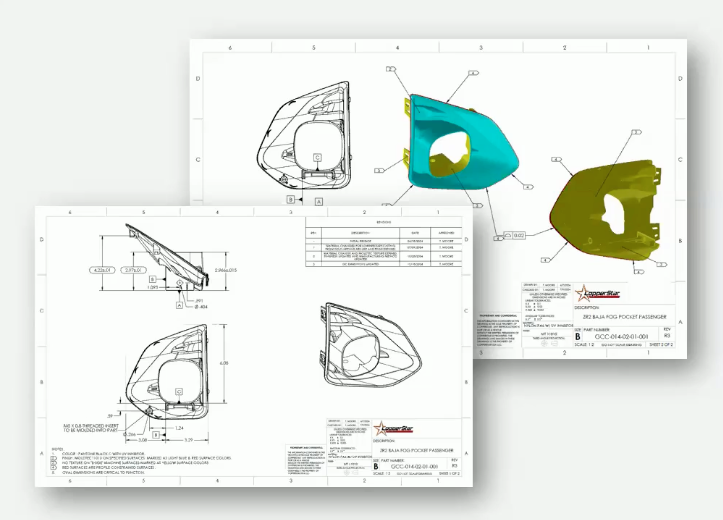

For the last 20 years, Interlink Engineering has provided clients with a complete engineering solution on-demand. They offer design, analysis, prototyping, and product process development.

“It could be individuals, inventors and stuff off the street, or companies,” Dylan Pratt, Owner and Director of Engineering at Interlink Engineering detailed. “Some companies are looking to supplement their engineering team or have us take on projects completely.”

In 2019, Interlink sold A3D Manufacturing their first HP 3D printer which laid the foundation for a partnership that would give their customers access to a full suite of design to manufacturing services.

“There is a lot of history between the two of us, but we continue to use A3D because of the great service and quick turnarounds,” Pratt said.

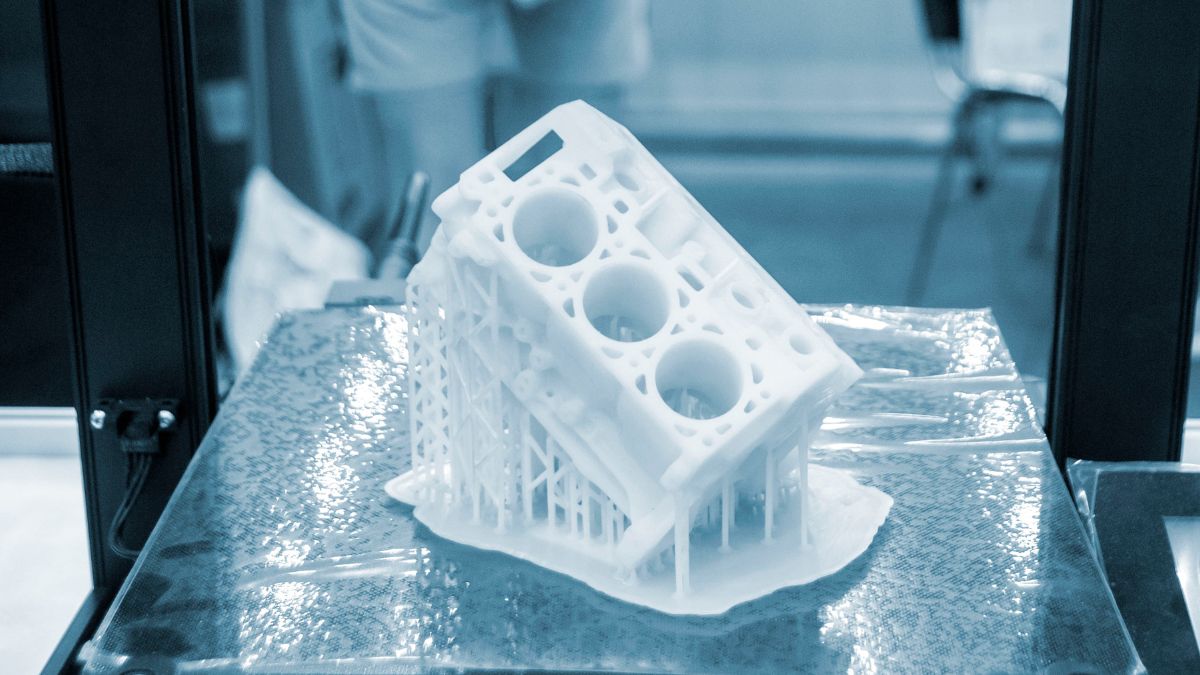

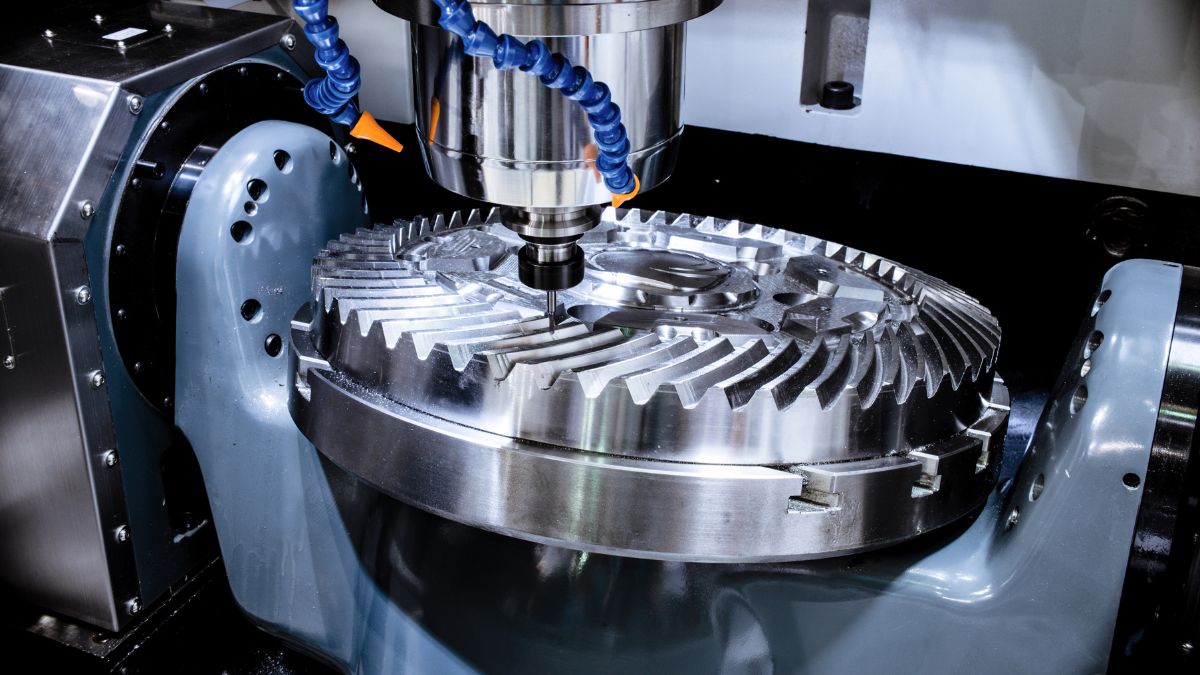

Interlink has taken advantage of most services A3D offers for their customers- 3D printing, injection molding, cast urethane, CNC machining and more.

“We do minimal manufacturing internally,” Pratt explained. “Anything that requires machining precision, higher accuracy or higher quality 3D printing, we are reaching out to A3D to do that.”

Pratt says the partnership is helpful to reassure their clients.

“Regularly, we have clients ask us if we can help them get things manufactured or into production,” Pratt shared. “Because of A3D, we can confidently answer that with a yes.”

“It’s a two-way street,” Michael Dymond, Account Manager at A3D, shared. “Some of these customers know they need manufacturing support, so we have Interlink get the CAD design or drawings generated. It’s a good referral-ship.”

A3D can meet customers wherever they are when they reach the production phase.

“There are stair steps along the way to production,” Pratt illustrated. “A3D has options all along that staircase. Sometimes it’s 3D print, cast parts, low production molds or getting machined. Event without a huge budget, you’ll be able to get to the point of releasing your product.”

Pratt says Interlink and A3D share similar values in business which makes the relationship so strong.

“There’s always someone to answer the call or email,” Pratt said. “The communication is a big part of what makes this run so smoothly.”

Click to read the A3D Interlink Engineering customer story.