In President Trump’s inaugural address, he said: “America will be a manufacturing nation once again.” And then the talk of tariffs started. Beautiful, beautiful tariffs. It’s left many small businesses and manufacturers asking, “What will President Trump’s tariffs actually do to the economy?”

The current new tariffs proposed by President Trump (as of the writing of this article) include a 25% additional tariff on imports from CA and MX, and a 10% increased tariff on imports from China.

Speculation now about how the proposed tariffs will impact the US economy range from hostile projections including increased inflation and positive takes that it will both increase household income and create millions of jobs specifically in the manufacturing sector.

While some businesses worry about President Trump’s tariff plans, others see opportunities.

In this article, we’ll cover how tariffs will affect manufacturers in North America and how nearshoring or reshoring projects with MaaS can help.

Ways Manufacturers Can Navigate Around Tariff Increases

For manufacturers, nearshoring, reassessing current suppliers, and other tactics are all on the table. Manufacturers can lean on both additive and traditional manufacturing services as part of their nearshoring strategy.

For US-based manufacturers, there’s near-term upside, but there’s also a lot of hard work. Suppliers you work with will need to be scrutinized. You may need to change suppliers to keep costs down.

For some manufacturers, costs may go up because they are locked into working with specific suppliers (think cobalt and computer chips.) Some of these costs can be offset by cutting costs in other areas. Whether it’s new tariffs or port lockouts, labor strikes, or other disruptive political situations, the global supply chain will always require agile and proactive strategies. This can mean you may need to:

- Diversify your supplier network

- Increase automation

- Weigh nearshoring/reshoring options

When you choose to work with local manufacturing providers like A3D you can actually bypass a lot of the issues that come along with the new tariffs.

What Are Manufacturers Saying You Can Do About Increased Tariffs Right Now?

Jeremy Tancredi, partner in West Monroe’s supply chain practice, suggests that manufacturers look not only at their tier 1 suppliers, but also tier 2 and tier 3 suppliers. They may not be as directly affected by new tariffs.

Alex Monino, VP of personalization and 3D printing at HP, suggests manufacturers should view the current tariff situation as a positive trend for nearshoring or onshoring because that is where additive shines – as a distributed and on-demand network of manufacturing capabilities that companies can use as a scale and cost-savings advantage.

Not only that, but traditional and additive manufacturing services brings jobs and manufacturing back to local communities, and echos some of the vision that Trump laid out in his inaugural address for igniting a resurgence of American-made manufacturing.

How Outsourcing and Reshoring Efforts Create Cost Savings

On-demand MaaS options add flexibility and scalability, saves money, and meets sustainability goals by producing parts and prototypes locally, cutting down on shipping and transportation costs as well as carbon emissions.

The key benefits of working with local manufacturing providers include versatility and cost savings.

Versatility in Manufacturing Options with MaaS

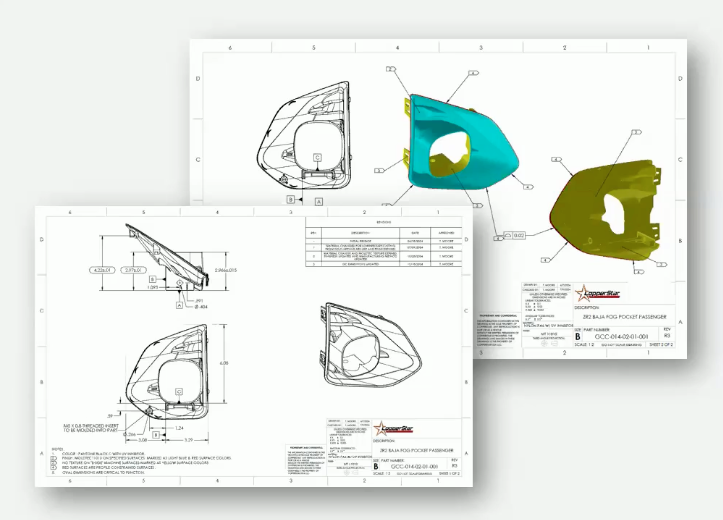

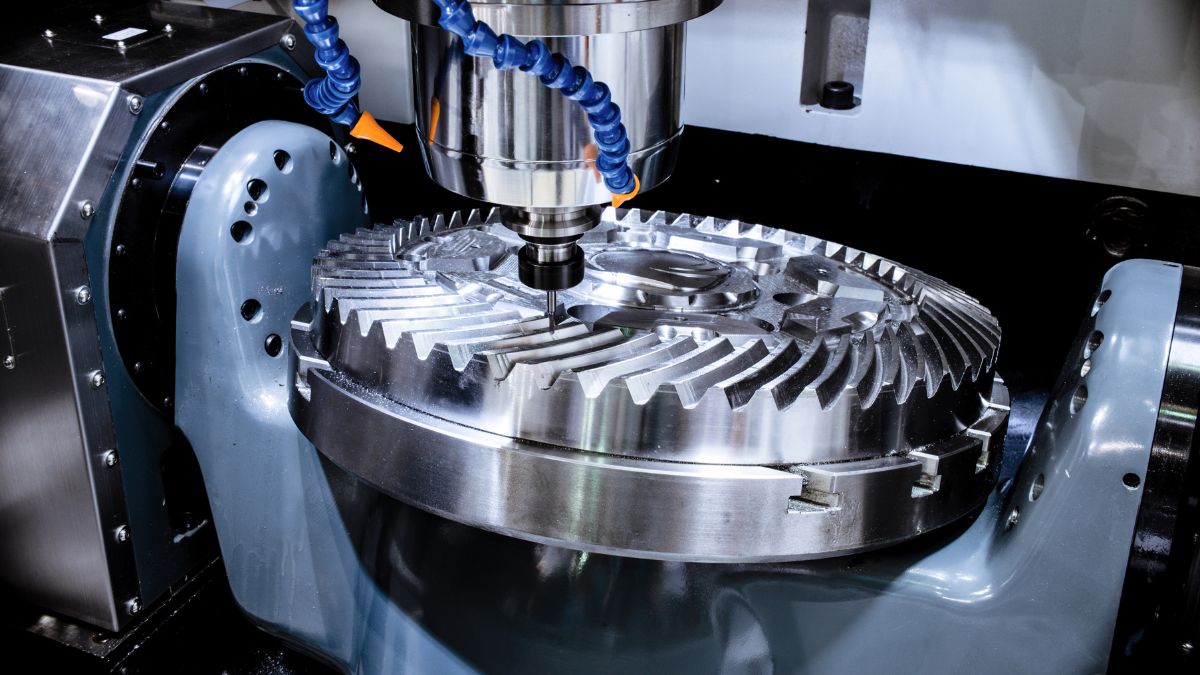

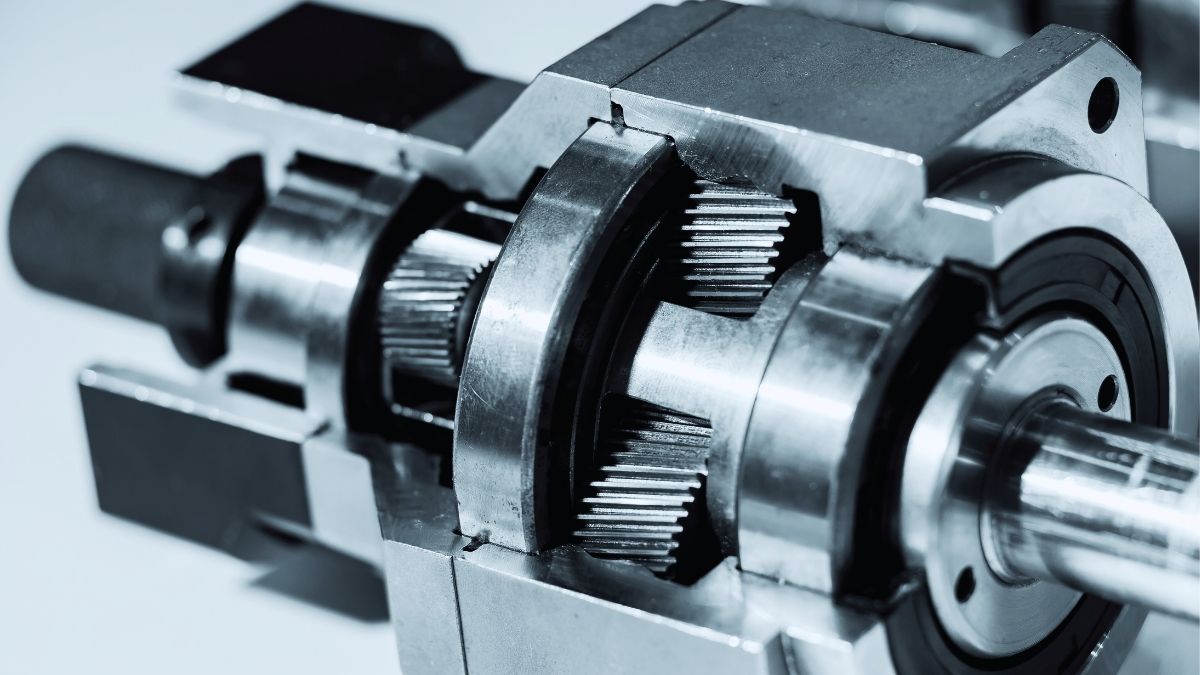

A3D’s manufacturing facilities include high-performance machines from HP, Formlabs, Markforged, Stratasys, and more. Whether you need 3D printing, 3D scanning, Cast Urethane, injection molding, or CNC machining services, A3D can deliver.

Get Only the Parts You Need with MaaS

You can also eliminate large inventories by creating only the parts and prototypes you need, on-demand. Scale up or down depending on your business needs and market demands. Interlink Engineering uses MaaS to scale production capacity when business spikes.

FitmyFoot uses MaaS to create only the parts they need on a customer-by-customer basis.

You can also save money because your designs can quickly and affordably be validated and created. Get an understanding of how much your part or prototype will cost ahead of time with online part quotes from A3D.

Partner with A3D Manufacturing for Your On-Demand Manufacturing Needs

Whether you need traditional manufacturing services, CNC, 3D Printing, 3D Scanning, or something else, A3D Manufacturing is your go-to manufacturer on demand.

Upload a part, get a quote, and see what you can do with A3D’s manufacturing services.

A3D is:

- Local: Based in North America out of Phoenix, Arizona

- Connected: Knowledgeable service that’s deeply connected to an extensive network of manufacturers and suppliers in the United States.

- Certified: An HP Certified Partner, ITAR-compliant, and AS9100 & ISO 9001:2015 certified.

- Versatile: Offering a range of services including traditional CNC machining, Injection Molding, 3D Printing, and 3D Scanning services based on your project or needs.

Get high-performance, high-quality parts, fast. Reach out to A3D Manufacturing today.