Material choices aren’t just a spec detail — they dictate performance, cost, and manufacturability. The wrong choice can mean wasted money, parts that fail in the field, and costly recalls. Procurement teams sometimes optimize for the lowest unit cost without considering material performance trade-offs (fatigue, toughness, or thermal performance). This post is to help engineers, manufacturers, and procurement teams make smart material and process decisions up front.

Why Materials Matter in Both Additive and Traditional Manufacturing

Material choices impact performance, budget process fit, volume, and more.

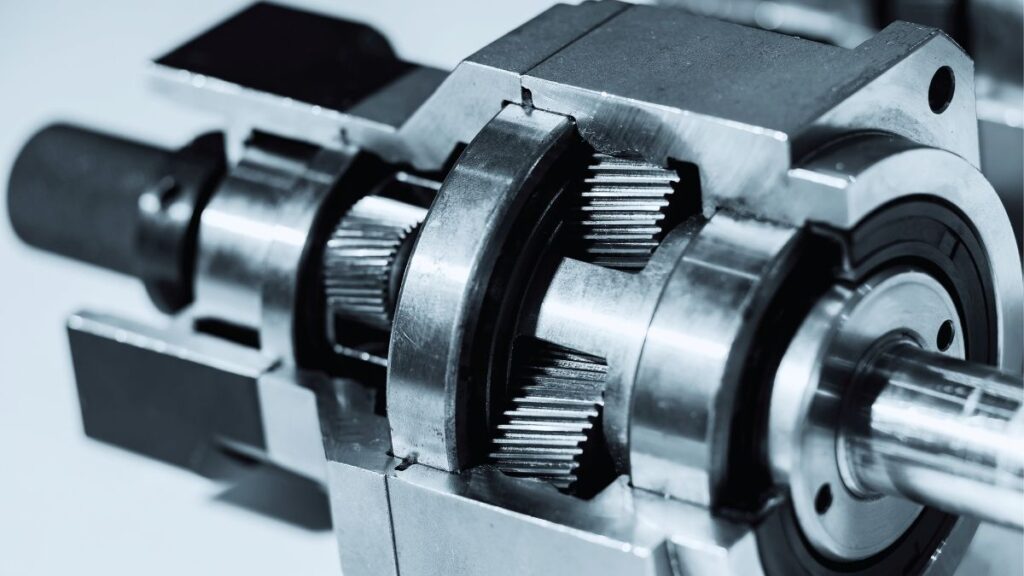

For part performance, think about tensile strength, fatigue resistance, heat tolerance, and vibration resistance. These things directly determine whether a part can survive in drivetrain, thermal, or ADAS environments. Choosing the wrong material, like using a polymer where an alloy is needed, is one of the top causes of in-field failure.

Material choices also directly impact budget. Think about raw cost, finishing, waste, and tooling. Raw material pricing is only part of the equation. Machining waste, finishing steps, and tooling requirements often add two to five times the theoretical material cost.

And when it comes to process fit, it can be difficult to determine if you need your part machined, printed, or hybridized. Using CNC on a geometry better suited for additive manufacturing can lead to 60-80% material waste, while printing parts that really require CNC tolerances can create fitment issues.

Whether you choose one process or another will be influenced by the volume you’re going for, too. Injection molding pays off only once tooling is amortized, meaning high fixed costs up front, low per-part cost at scale. For tens to thousands of parts, cast urethane or hybrid additive manufacturing can work. While additive is often considered a low volume manufacturing method, it is not uncommon for it to be the more economic option well into the thousands of parts.

That’s a lot to consider. So, how are you supposed to determine which process and material to go with?

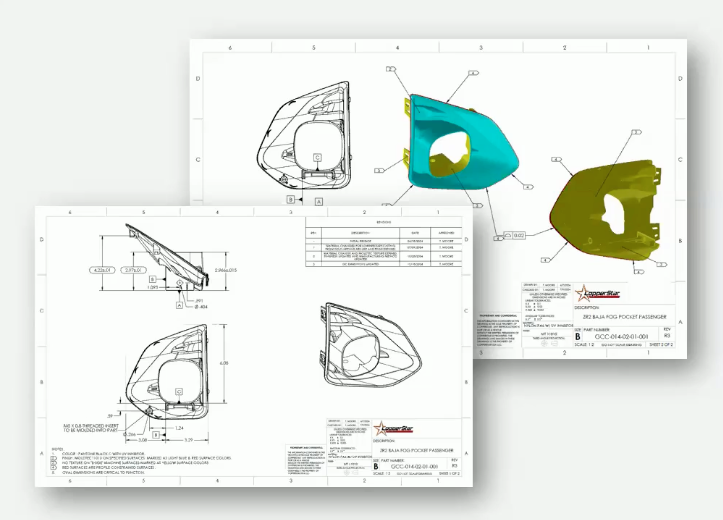

Oftentimes, you’ll need to work with a manufacturing expert with extensive experience in design for manufacturing (DFM) reviews. DFM review at A3D Manufacturing means we’ll review your part geometry and requirements and match it to processes and materials that best fit your project. We provide alternatives (both material and process) and crunch the numbers so you can find the most economical way to get your part made.

Here’s a quick look at material considerations for automotive aftermarket parts:

Material Considerations for Automotive Manufacturing

| Material Type | Strengths in Automotive | Typical OEM Uses | Typical Aftermarket Uses | Drawbacks | Selection Scenario |

|

Metals (High-strength steel, aluminum alloys) |

High strength-to-weight, crash energy absorption, recyclable | Chassis, body panels, engine blocks | Suspension upgrades, accessory mounts, brake calipers | Corrosion (steel), higher cost and weight | When safety and durability are paramount, think EV frames for battery protection |

|

Polymers / Plastics (ABS, Nylon, Polypropylene) |

Lightweight, corrosion-resistant, low-cost molding | Bumpers, interior trim, fuel tanks | Custom dashboards, intake manifolds, body kits | UV degradation, lower heat tolerance | Mass-produced non-structural parts or affordable aftermarket accessories |

|

Composites (Carbon fiber reinforced polymers, fiberglass) |

Exceptional strength-to-weight, vibration damping | Hood panels in sports cars, EV battery enclosures | Aero kits, lightweight wheels, hood scoops | High cost, repair difficulty | Performance upgrades where weight savings boost handling or acceleration |

|

Ceramics (Silicon carbide, alumina) |

Extreme heat resistance, wear resistance | Brake pads, catalytic converters | High-performance brake rotors, exhaust coatings | Brittle, expensive | Friction-heavy applications like racing brakes in aftermarket |

|

Advanced Alloys (Titanium, Inconel) |

Low density, high corrosion resistance | Exhaust systems, wheels in luxury vehicles | Turbo components, lightweight pistons | Very costly, hard to machine | Niche high-end aftermarket for tuned engines or weight-critical builds |

How Do You Pick the Right Material and Process?

A3D’s Decision-Making Framework

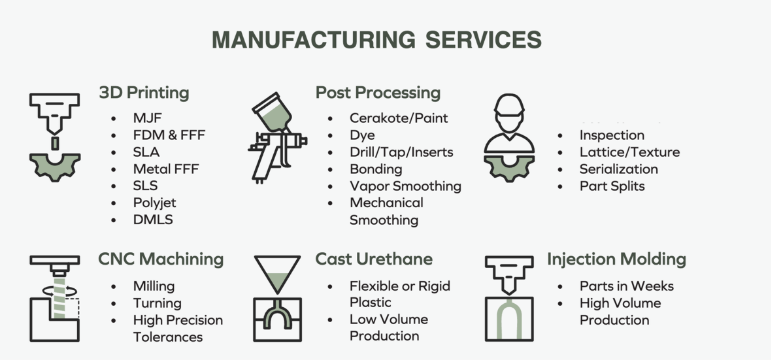

At A3D, we take pride in being a leading innovator in manufacturing. As a technology-agnostic manufacturer, we specialize in creating custom plastic and metal components that cater to companies of all sizes. Our extensive capabilities encompass industrial-grade additive manufacturing, accompanied by a range of finishing and post-processing options. We also excel in traditional manufacturing techniques such as CNC, injection molding, urethane casting, and sheet metal cutting/bending.

Understanding which type of process and material you need can be difficult, which is why when scoping a project, we offer alternative material and process options, so you get a part that matches your specifications and intended use.

In general, you can look at manufacturing process selection through this high-level lens:

- Additive Manufacturing: Best for complex geometry, weight savings, low-volume, customization

- Traditional Manufacturing: Use when you need high precision, tight tolerances, and larger production volumes

- Hybrid: Near-net AM (think additive + CNC combo) used when you have “this is the only way to make this” scenarios

For a full list of all of A3D Manufacturing’s processes, materials, finishes, tolerances, lead times and more, take a look at our brochure which covers both additive manufacturing and traditional manufacturing details:

A3D Manufacturing: A Comprehensive Guide to Our Services

What sets A3D Manufacturing apart is our holistic approach as a true prototype-to-production manufacturer. Whether you require a few prototypes or up to tens or hundreds of thousands of parts, we have you covered. We also cater to long-tail production and maintenance, repair, and operations (MRO) requirements. Our virtual warehousing and on-demand production capabilities ensure that you receive your products just-in-time, optimizing your supply chain.

Practical Examples for Material and Process Choices

Here are some common practical examples where materials and processes may shift during development:

- Printing PA12 prototypes now, and using injection molded PA 6 for production

- Starting with cast urethane bridge production while steel tooling is cut

- Starting with fiber reinforced FDM brackets and mounts for prototype, then shifting to sheet metal for production

- Using MJF PP technology for fluid reservoirs during a pilot program, then shifting to molding + hot plate welding or blow molding for production

A3D Manufacturing: Matching You with the Right Material and Process for Your Parts

The material you choose determines not just performance but also cost and process fit. With A3D, you don’t have to guess — you get a process and materials-agnostic framework from manufacturing experts that review your build.

At A3D, our materials science engineer and manufacturing experts review to ensure the selected material and process meets the application’s mechanical and environmental demands and prevent costly mistakes. We provide a process-agnostic stack and real engineering guidance to balance material properties, cost, and process fit.

Whether you order fast via Auto-Checkout or work consultatively for requirements and tolerances, every job goes through the same A3D HQ QA and documentation steps.

Ready to build? Get an instant quote if you need 3D printed parts or replenishment or contact us for a more consultative approach (DFM, requirements review, and production planning).

Want to know more? Download the Automotive Aftermarket Playbook