CopperStar USA Mission & What They Do

CopperStar USA’s mission is to invent, test, and supply smart made-in-America automotive aftermarket products that people love.

Founded in Chandler, Arizona, they design, test, and produce custom automotive parts tailored to customer needs, often incorporating user feedback into future designs. Their most popular parts include:

- The NOVA Wire Management series for organizing vehicle wiring

- Specialized mounts like the BANKS iDash Vent Mount for Chevy Colorado or GMC Canyon (Gen 2) trucks, aimed at clean, functional integrations

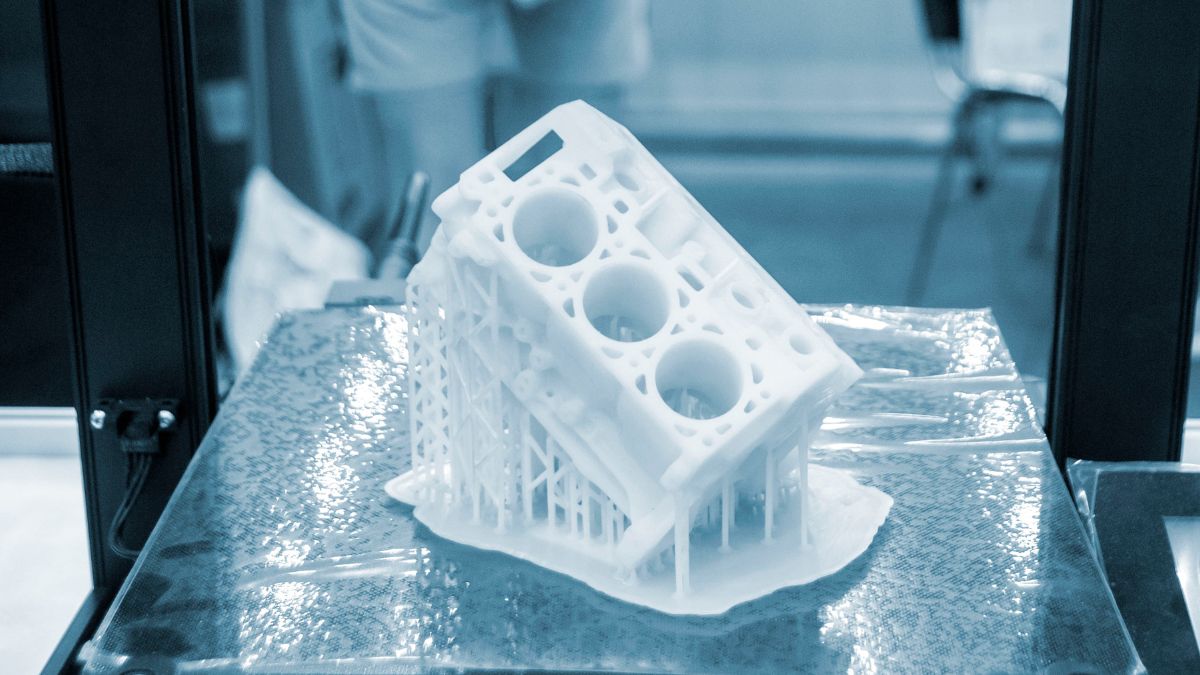

CopperStar USA started as a passion project for owner Taylor Moore (also the Director of Manufacturing at A3D), who has a background in vehicle modification and design. While in college, he built bumpers and became familiar with sheet metal work. After moving and losing access to traditional tools, he turned to 3D printing. In 2019, after getting a new truck, he designed the NOVA roof cable pass-through system to solve sealing issues with antennas, opting for HP Multi Jet Fusion (MJF) technology for its suitability in low-volume production.

“I got a new truck, and I love off-roading and modifying vehicles,” says Taylor Moore, “I designed a new roof cable pass-through system. That’s the Nova. I didn’t want to go through injection molding to make it. HP MJF is perfect for this part because it’s low volume.”

Starting a Business Without Capital Investment: The Manufacturing as a Service + Distributor Model

Starting a side business in automotive accessories presented several hurdles for Taylor. He wanted to avoid high upfront costs like tooling or inventory overhead, while ensuring parts were durable and high-quality. Traditional manufacturing methods like injection molding required significant investment, and basic FDM (Fused Deposition Modeling) 3D printing didn’t meet longevity standards for vehicle parts.

Additionally, Taylor needed flexibility to iterate designs based on customer feedback without financial risk. Scaling from personal use to selling required a just-in-time model to minimize debt and allow for quick changes, such as adjusting bolt lengths or adding features.

Working with a distributor and A3D’s manufacturing as a service gives Taylor an outlet for his creativity through design work, while keeping the time investment minimal.

“Using manufacturing as a service allowed me to start the company with no tooling, no debt. I only had a website and my own sweat equity.”

-Taylor Moore, Director of Manufacturing at A3D and Owner of CopperStar USA.

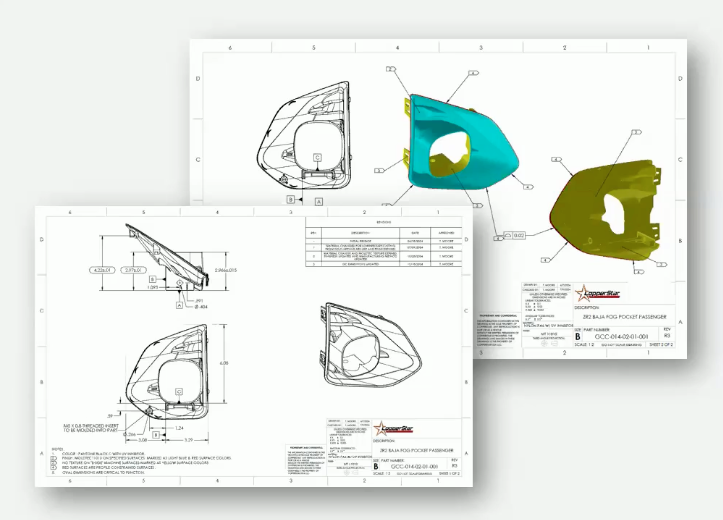

How CopperStar Uses SOLIDWORKS, 3D Printing & Post Processing

Taylor turned to A3D Manufacturing for production, starting in March 2020. Using their HP MJF 3D printing capabilities, he produced parts in small batches (e.g., 1-25 at a time), and dyed and mechanically smoothed the parts with the DyeMansion Powershot surfacer for a professional finish.

This build-to-order approach allowed CopperStar to launch with no tooling or debt — just a website and sweat equity. When orders came in, Taylor ordered from A3D, packaged, and shipped, avoiding inventory costs.

For design, Taylor uses SOLIDWORKS. “I do use SOLIDWORKS to do all the design work,” he says. He also has a partnership with GM, receiving CAD models directly from the manufacturer for perfect fits. “They will actually send me CAD models… which allows me to get exactly perfectly fitting parts every single time.”

As volume grew, Taylor expanded capabilities with A3D, moving some products like the fog pocket shroud from prototypes to cast urethane molding, and eventually full injection molding. “That whole product lifecycle was done at A3D,” Taylor notes.

Shifting to a distributor-only model with Colorado Canyon Enthusiasts simplified operations. Now, Taylor orders larger batches (10-200) from A3D when the distributor places requests, maintaining just-in-time production.

“It’s been great having Colorado Canyon Enthusiasts as my distributor. It’s allowed me to focus more on making other products instead of managing day-to-day activities.” – Taylor Moore, Director of A3D Manufacturer and Owner at CopperStar USA

On tolerances and testing: Taylor’s parts are cosmetic and don’t require extensive simulation, but designs incorporate drainage features for water and use automotive-grade materials like nylon 12. For the rear camera mount, the housing protects electrical components (already weatherproofed) with silicone sealing and drainage.

CopperStar Key Wins with A3D & Colorado Canyon Enthusiasts

The partnerships with A3D and Wyatt at Colorado Canyon Enthusiasts enabled CopperStar to grow sustainably. Taylor started with direct sales but transitioned to one distributor, increasing volume while reducing stress. “By going through a distributor… I sell more volume, and I actually end up making more money in the long run. But I also keep my stress level down,” he says.

Benefits include:

- Low Overhead: No inventory maintenance (parts built to order in 2-3 weeks)

- Flexibility: Easy design iterations without affecting production runs

- Quality and Aesthetics: MJF provides a stock-like texture that blends seamlessly. “The quality of that part is so high… people really like that. They can’t believe that it’s a custom component.” -Taylor Moore, Director of Manufacturing at A3D Manufacturing

- Scalability: From prototypes to injection molding, all handled by A3D, with the only capital investment being tooling for molds for non-3D printed products

- Made in USA: Most parts are American made, enhancing branding. Shipping costs are reduced, and logistics are easier for receiving finished goods.

CopperStar now has a catalog for various trucks, with products like gauge pods praised for their integration. “We want that product to integrate into the vehicle and basically not look like it wasn’t stock,” Taylor emphasizes.

ROI comes from higher volumes at lower costs, supporting family off-road trips and community involvement, like administering the Bison Owners Group on Facebook (An off-roading enthusiasts meetup group).

“You know, most people spend money on their hobbies. I happen to make money on my hobby.”

What’s Next for CopperStar?

CopperStar remains a passion project, focused on artistic expression through design.

“Using A3D enables me to simplify CopperStar, which lets me spend more of my time outside of work (A3D) enjoying the outdoors with my wife and family rather than spending that time managing CopperStar’s inventory.” – Taylor Moore, Director of A3D Manufacturing and Owner of CopperStar

Technologies like advanced 3D printing excite him for future innovations. “I just like seeing my products on other people’s trucks… It’s satisfying to me.”

For more information, visit CopperStar USA or purchase through Colorado Canyon Enthusiasts. Follow CopperStar USA on Facebook and Instagram for updates.