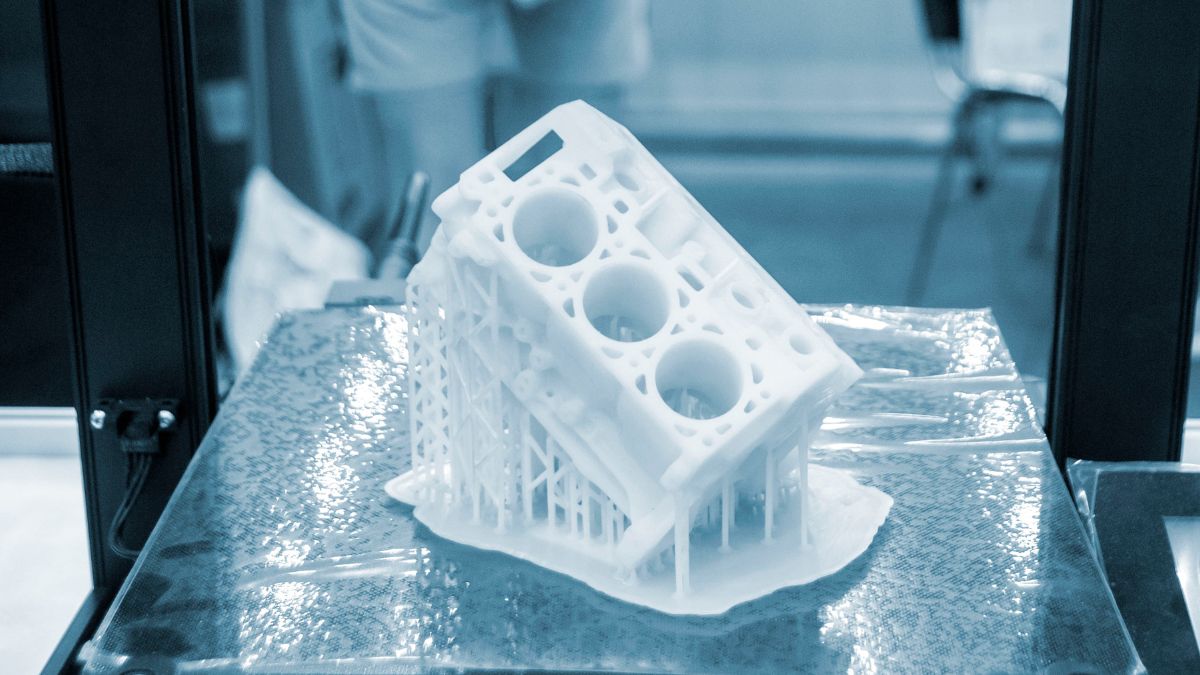

Additive Manufacturing is everywhere, but you may not even realize it.

One of our customers, a leader in food and beverage packaging, applies the carriers that you see holding together two giant ketchup bottles at Costco, or maybe a six pack of your favorite bubbly beverage.

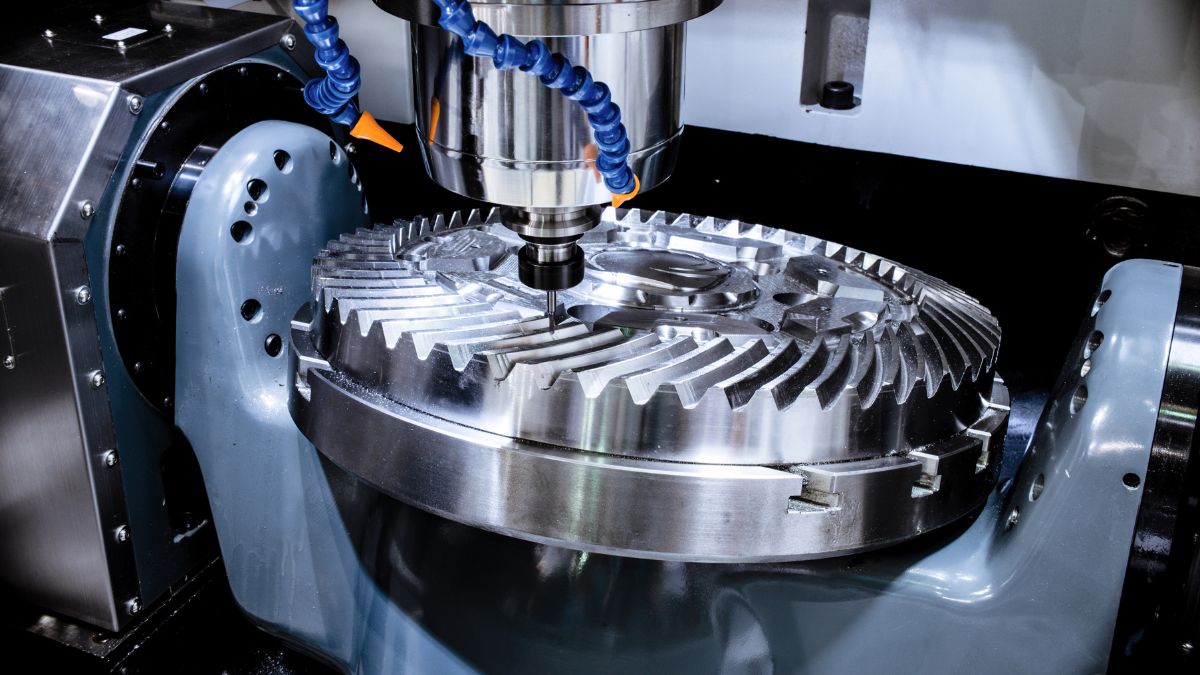

They previously used a traditional CNC machining process to create the automated tooling that installs the carrier. It turns out CNC machining was actually a more expensive and less straight-forward workflow than using additive manufacturing solutions.

When they came to us, they had one specific goal in mind:

Create a more efficient, cost-effective approach to meet growing demand.

Spearheaded by their Director of Operations and Industrial Design Engineering Manager, they asked A3D Manufacturing how we could help.

Assessing the Situation: Why the Switch from CNC Machining to 3D Printing Carbon Fiber?

Anyone working in a machine shop knows that minimizing lead times is key. Things like material weight, part size limitations, and part costs can also tank a project fast. For this customer, it came down to four critical factors:

- CNC was overkill for their needs

- Material choices added unnecessary weight

- Demand spikes put machine shops at capacity

- They needed to print large parts

High Costs and Long Lead Times: This customer previously relied on CNC machining with aluminum, which was wasn’t quite the right solution, turned out to be rather expensive, and put their lead times out to 4-5 weeks due to the fluctuating bandwidth and consumer demand.

Material Weight: Aluminum components added unnecessary weight, requiring more robust equipment and slightly increasing shipping costs.

Scalability Issues: Spiking demand overwhelmed CNC machining capacity, creating bottlenecks.

Part Size Limitations: Some parts were too large for even large format 3D printer build envelopes, requiring innovative solutions.

Solutions Implemented: Markforged FX20 and Manufacturing as a Service

This customer partnered with Hawk Ridge Systems and A3D Manufacturing to transition to a 3D printing ecosystem. Because they were a Hawk Ridge Systems customer, they used their built-in discount for their first order with us, got training, and implemented an entirely new workflow.

Key solutions included:

3D Printing with Onyx and Fiber Reinforcement: They replaced CNC-machined aluminum with 3D-printed parts using Onyx filament and carbon fiber reinforcement for strength and stiffness, which reduced costs and weight.

Heat-Set Inserts: Instead of machining threads into aluminum, they adopted heat-set metal inserts, upholding the need for a high-fidelity assembly solution.

Lap Joints and Bonding: For parts too large for the FX20’s build plate, A3D coached the customer on splitting parts and bonding them with two-part epoxy using lap joints, enabling them to push beyond the size limitations of the already sizeable FX20 build envelope.

In-House Validation and Training: A validation study confirmed 3D printing’s viability, with SolidProfessor training empowering their engineers to adopt additive manufacturing.

A3D Voucher: The customer used an A3D voucher for a 20% discount on 3D printing services, easing the transition.

Results When You Partner Up: A3D Manufacturing + Hawk Ridge Systems + Markforged

This customer’s shift to 3D printing completely changed their packaging automation process for the better:

They saved money and time.

3D printing reduced costs significantly compared to CNC machining, with equal or faster turnaround times, eliminating delays.

They lightweighted their parts.

3D-printed components printed with the Markforged FX20 were lighter, reducing equipment strain and slightly lowering shipping costs.

The Markforged FX20 on the A3D Manufacturing Shop Floor

They made more durable parts.

Stress tests, including intentional misalignment to force production collisions, validated the durability of 3D-printed parts.

They met demand.

Additive manufacturing bypassed CNC material and sourcing constraints, enabling them to meet spiking demand efficiently.

By solving cost, time, and scalability challenges, they not only optimized production but also positioned themselves for future innovation with an in-house additive ecosystem.

Not only that, but they got two bonuses when they switched their workflow: Reduced reliance on the global supply chain and a new fun toy to play with in the shop!

- American-Made Efficiency: By cutting out overseas middlemen, they embraced a streamlined, U.S.-based production model.

- Innovation and Fun: The team enjoyed experimenting with “new toys” like the FX20, boosting morale and creativity.

Optimize Your Manufacturing Workflows with A3D Manufacturing

At A3D Manufacturing, we specialize in services for the North America market like 3D printing, CNC machining, and injection molding, providing businesses with the tools they need to streamline operations and improve resilience.

Ready to optimize your manufacturing process, reduce costs, and scale up?

We have manufacturing experts ready to connect you with the right solutions, technologies, and materials to ensure your parts are high-quality, on-budget, and on-time.

Get high-performance, high-quality parts, fast. Get in touch with A3D Manufacturing to see how MaaS can help your business scale.