Precision — the Devil is in the Details

When you’re in the business of making things — precision matters. For brands like Lego, an inaccurate part could mean you’re missing the final piece to complete your four-hundred-dollar Star Wars Deathstar replica. It’s not exactly a life and death situation, but it’s not, like, ideal. For an automotive company, it could mean a huge loss in revenue that ripples for years to come. Or worse. For a medical device company, precision absolutely is a life and death situation.

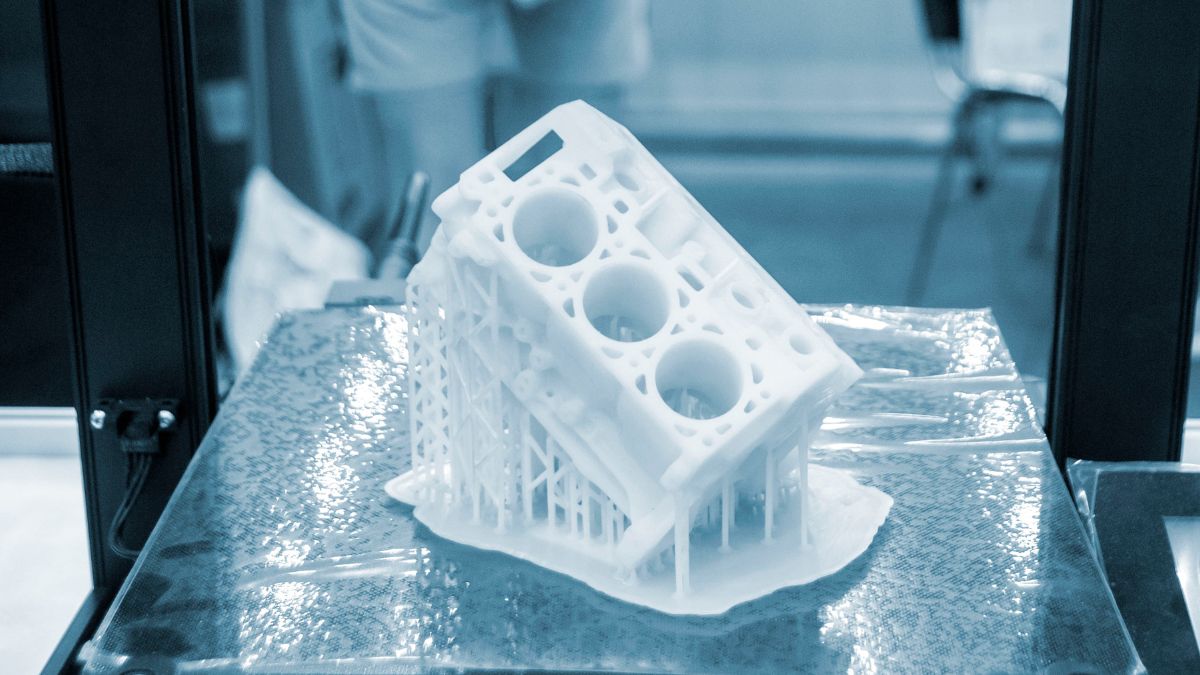

No matter the industry, precise and accurate 3D printed parts are mission-critical for manufacturers.

Lego has been making injected mold parts since the 1950s. Today their manufacturing process yields parts accurately down to 1/200 mm. But for other industries such as the medical device industry, precision, specifically when it comes to intricate details, is calculated in micrometers. Micrometers are used to measure the thickness and diameter of microscopic objects, typically for structures in the medical implant and bioprinting space.

The requirement of precision in production 3D printing goes beyond an acceptable prototype; it’s about reliability and consistency. In the aerospace industry, for instance, every component must meet exact standards, every time. Automotive parts require similar meticulous attention, ensuring vehicles are safe and reliable. Medical implants and tools are used within the human body; any error must fall within a tolerable range (tolerance level). The proper function of parts has major implications on health and safety, especially in these fields.

What exactly is precision in 3D printing?

“Precision describes how close measured values are to each other [7]. Precision refers to the fabricated physical product. Accuracy describes how closely a manufacturing machine’s output conforms to a tolerance within a specified dimensional range.”

Or put differently, if you’re shooting an arrow at a target, precision is how consistent and reproducible your shots are, and accuracy is how close your shots are to where you were trying to land on the target.

When it comes to 3D printing, you want your parts to be both precise and accurate and as close to NNS (Near Net Shape) as possible so that you minimize post-processing activities and get a part that’s almost in its final form. Not only that, but repeatability and resolution are equally as important, and often dependent upon the type of 3D printing tech you go with.

“When dealing with AM, accuracy, repeatability and resolution are highly dependent on the technology and often on the individual machine that is being used to manufacture the final product.”

Repeatability: The 3D printer’s capabilities pertaining to consistent output over time.

Resolution: The smallest measurement a 3D printer can reproduce.

Achieving Precision: The Key to High-Quality 3D Printed Parts

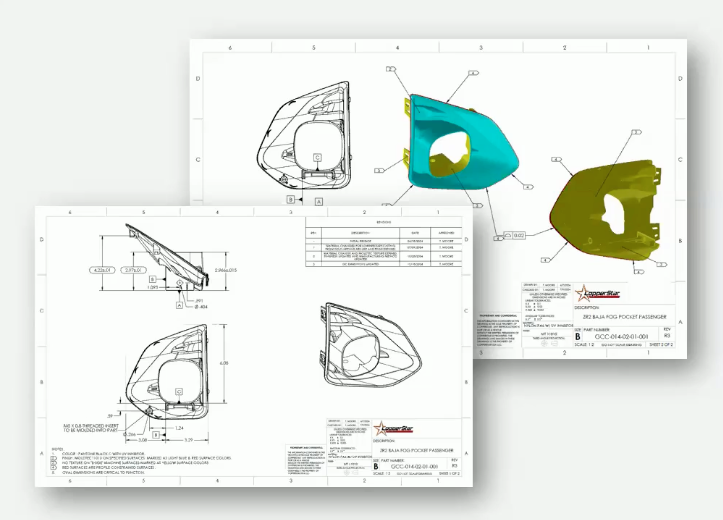

Ensuring precision is critical to meeting stringent industry standards and producing functional parts that perform as expected in high-stakes environments. Meeting standards starts with design and engineering. Parts must be designed not only for proper function, but also within the constraints of the intended manufacturing methods. Generally, 3D printing technologies cannot achieve such tight geometric tolerances as many traditional manufacturing methods, such as CNC machining, EDM processes, or injection molding. There are also material and surface-finish limitations associated with most 3D printing technologies. While these inherent limitations present obstacles to meeting standards, they can often be overcome through proper planning at the design stage.

Tips for Meeting Industry Standards

Here are some tips for meeting industry standards in 3D printing: carefully select materials, optimize print settings and orientations, manage files effectively, and utilize post-processing techniques to enhance precision:

- Material Selection: Early in the design process, ensure that material requirements can be met by the materials that are printable by the intended technology.

- Orientation and Print Settings: Being intentional with print settings and orientations can ensure best-possible geometric tolerances and surface finishes. Becoming educated on the target printing technology improves the ability to properly set up print jobs.

- File Management: Many printing technologies require a conversion from a parametric CAD file to a tessellated, triangulated file. This conversion causes smooth curves to be broken up into straight, flat sections. However, designers must realize that they do have control over file resolution during parametric-to-triangulated file conversion.

- Post-Processing: Depending on the application, post-processing can enhance the precision of a part, either through additional machining, smoothing, or other finishing techniques.

A3D – Trusted Experts for Precise & Accurate 3D printing

3D printing offers incredible freedom and speed in creating unique and complex parts, yet precision remains a perceived barrier to widespread adoption across industries.

At A3D, we are trusted experts in precise and accurate 3D printing. While precision may be seen as a barrier in the industry, 3D printing offers tremendous possibilities for creating unique and complex parts. With smart design and our expertise, precision is within reach.

Sources

LEGO. Quality in every detail – LEGO® History – LEGO.com US. Last access 09/14/2023

International Conference on Advanced Manufacturing Technologies. “Prescribed precision for medical products obtained with additive manufacturing technologies.” 2022.