Why Does Quality Assurance Matter in 3D Printing?

Producing high-quality 3D parts that are precise and quality-assured does not happen by accident. It calls for attention to detail and qualified expertise in additive manufacturing software and hardware systems and tools — which requires time, education, and commitment.

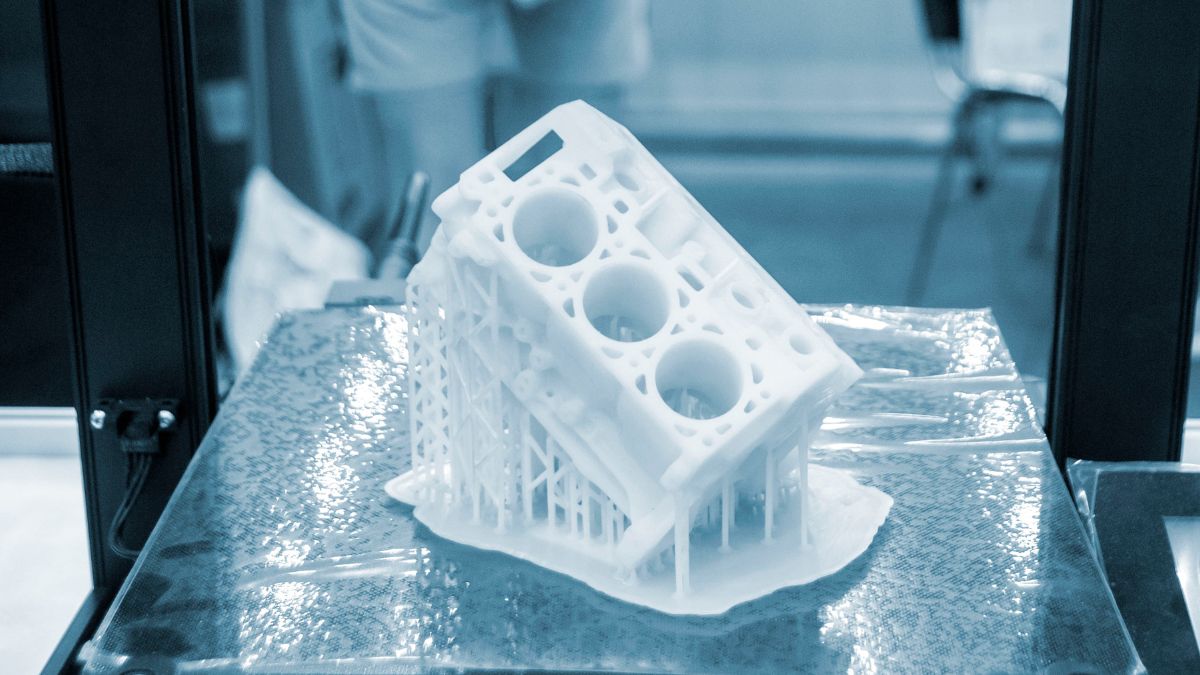

Since its inception, 3D printing has been a transformative force in the world of manufacturing, allowing companies to create more innovative parts and products, reduce material waste in the manufacturing process, and simulate product performance before ever actually producing the parts and products. 3D printing enables us to offer unparalleled customization, speed, and efficiency to sectors ranging from aerospace to healthcare.

Not all additive manufacturing partners see commitment to quality as important as we do here at A3D Manufacturing. Our dedication to quality and reliability is unwavering, making our quality assurance protocols critical to our operations.

That’s why we continue to add certifications like our most recent addition to our list of certifications — our HP Digital Manufacturing Partner (DMP) certification. Now A3D Manufacturing is both HP DMP certified and ISO 9001 certified.

A3D Manufacturing’s HP Digital Manufacturing Partner (DMP) Certification

A momentous accolade in our journey, the DMP certification is a testament to A3D Manufacturing’s leadership in the 3D printing arena. Achieving this certification underlines our dedication to advanced additive manufacturing processes, industry-standard certifications, and high-quality volume job production. Certified by HP, this certification is only issued to manufacturers who HP determines to be capable of representing their technologies.

“The Digital Manufacturing Network (DMN) and DMP certification identifies A3D Manufacturing as a leader in the 3D printing space. We’re thrilled to include them as the latest partner in our esteemed community.”

-Gregory Elfering, Head of Americas, 3D Printing at HP

A3D Manufacturing’s ISO 9001 Certification: A Testament to Our Quality Commitment

Our allegiance to quality assurance in 3D printing is epitomized by our adherence to the ISO 9001 certification. This globally acknowledged benchmark reiterates our pledge that each product emerging from A3D Manufacturing undergoes rigorous quality control measures, bolstering our stature for unmatched reliability and consistency.

Quality Assurance Strategies at A3D Manufacturing

Our approach to ensuring immaculate 3D printed outputs includes design evaluations, collaborative engineering, process control and machine maintenance, as well as post-production inspections:

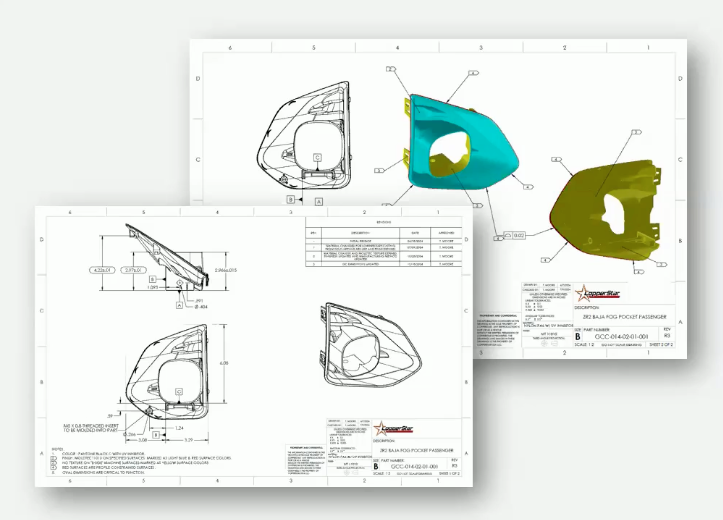

- Design Evaluations with Collaborative Engineering: Before printing, each 3D model undergoes stringent scrutiny for design robustness and printability. Further, A3D’s unique service encourages collaboration with engineers, recommending design enhancements for optimized 3D printing outcomes. Each part is reviewed by a human person knowledgeable in Designing for Additive Manufacturing, giving our customers guidance before we even prototype.

- Process Control & Machine Maintenance: Beyond tracking parameters like temperature, humidity, cycle counts, A3D Manufacturing underscores the importance of routine machine maintenance. Recognizing that pristine machinery is pivotal for unparalleled outputs, our maintenance regimens ensure operational excellence. Collaborating with original equipment manufacturers, we’ve found that our robust maintenance plan affords our equipment higher up time than others in the industry.

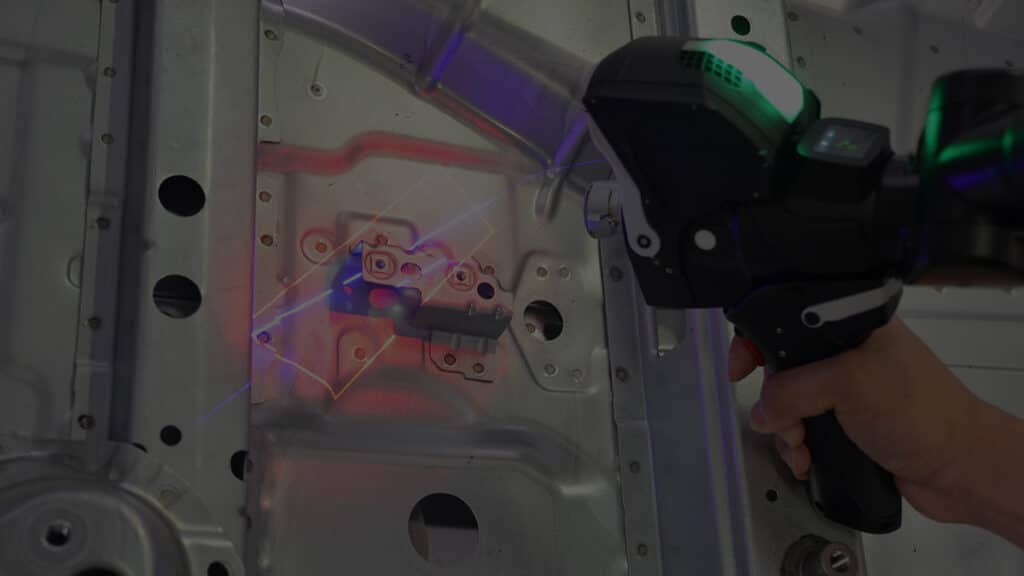

- Post-Production Inspections: Following rigorous design evaluations and process controls, we further affirm quality through exhaustive inspections. This involves visual assessments, dimensional checks, and functionality tests, significantly enhanced by the Hexagon Absolute Arm 85 3D Scanner. Customers can request Production Part Approval Process (PPAP), Capability Index (CPK), and First Article Inspection Reports (FAIR) in accordance with the latest AS9102 format.

Process Control & In-House Machine Maintenance

A hallmark of our commitment to operational excellence lies in our emphasis on both monitoring crucial parameters and upholding the pristine condition of our machinery. Notably, A3D Manufacturing stands apart due to its renowned training programs, empowering our technicians with the expertise to service our own machines. This in-house capability significantly reduces unplanned downtime, ensuring that we consistently maintain quality and timely deliveries. By prioritizing regular maintenance and leveraging our specialized training, we guarantee that our equipment not only meets, but often surpasses, industry uptime standards, offering unparalleled outputs to our customers.

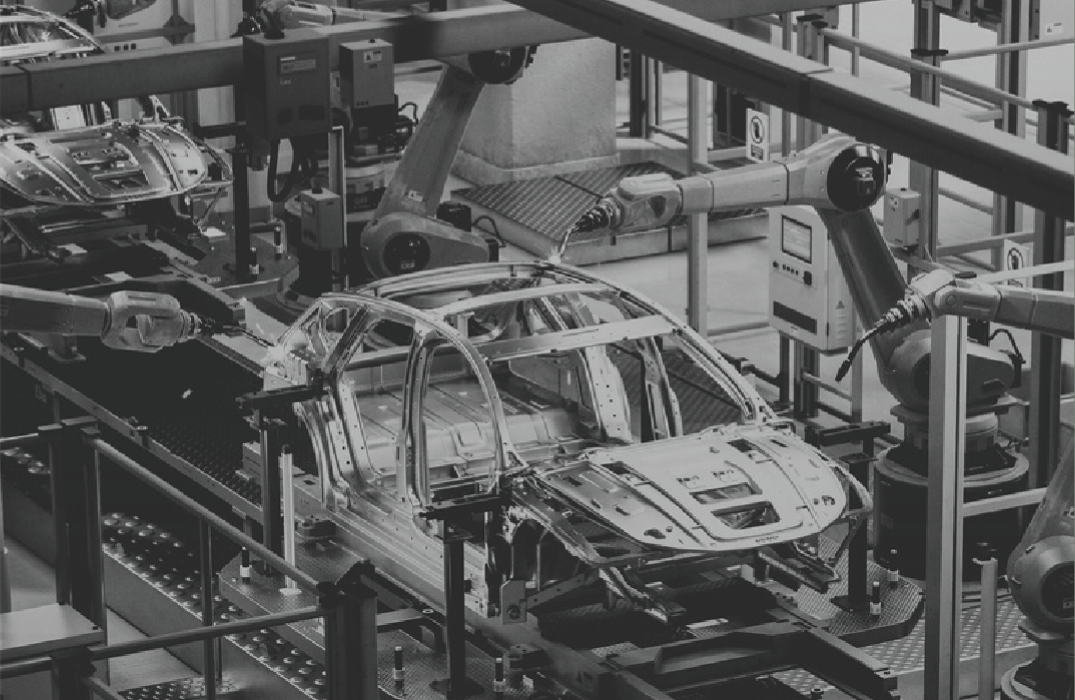

Transitioning from Subtractive to Additive Manufacturing in Aerospace

In the aerospace realm, the metamorphosis from subtractive to additive manufacturing marks a transformative evolution. Whereas subtractive methodologies typically involve chipping away from a solid material, additive techniques, such as HP’s Multi Jet Fusion (MJF), construct parts layer-by-layer, offering unmatched geometrical flexibility.

However, this innovative approach brings forth its own set of challenges. Unlike traditional methods where in-process inspections are standard, such inspections for technologies like Multi Jet Fusion are not feasible. Given MJF’s layer-by-layer construction, mid-process inspections could jeopardize part integrity. This necessitates avant-garde quality control measures, as implemented by A3D Manufacturing, to guarantee unwavering standards in scenarios where conventional quality checks are redundant.

This paradigm shift underscores the groundbreaking nature of additive manufacturing, compelling industry stalwarts to reimagine quality assurance paradigms. In this evolving scenario, A3D Manufacturing stands at the forefront, ensuring relentless commitment to excellence.

Engage with A3D Manufacturing

A3D Manufacturing’s ethos on quality assurance remains clear and unwavering and is showcased by our commitment to obtaining certifications like HP Digital Manufactuing Parnter (DMP) certification, as well as our ISO 9001 certification.

With our enterprise-grade 3D printing technology, rigorous quality protocols, and the recent HP partnership, we present a future-oriented blueprint for part production that promises reliability, consistency, and unmatched excellence in 3D printing.

Interested in harnessing the transformative power of 3D printing for your business?

Dive deeper into the world of additive manufacturing and explore the myriad possibilities that A3D Manufacturing can offer. Whether it’s insights, collaboration, or cutting-edge product solutions, we’re here to guide and partner with you. For further information or to initiate a conversation about your manufacturing needs, feel free to contact us or visit our website.

Stay updated with A3D Manufacturing’s latest advancements by following us on Facebook, LinkedIn, Instagram, and YouTube.

Frequently Asked Questions About ISO 9001 for Additive Manufacturing

Is A3D Manufacturing ISO 9001 certified?

Yes. A3D Manufacturing obtained their ISO 9001 certification in June 2021 and continues to recertify on a regular basis to maintain their ISO 9001 certification.

What are the benefits of working with an ISO 9001 certified additive manufacturing company?

ISO 9001-certified companies have passed an independent audit of their commitment to quality management processes and principles, so customers can reap the benefits. ISO 9001 quality management principles ensures customers receive high-quality services and products, with business benefits such as increased customer satisfaction and improved understanding of quality objectives, and a better managed supply-chain for a stable flow of goods and services. Read more about the quality management principles outlined in the ISO 9001 certification.

Is A3D Manufacturing HP DMP certified?

Yes. A3D Manufacturing obtained their HP DMP certification in August 2023 and is committed to maintaining this certification.

What is the HP DMP certificate?

HP’s (Hewlett Packard) Digital Manufacturing Partner (DMP) certification is issued to leading manufacturers who meet HP’s additive manufacturing standards for processes, quality management and job production.