In today’s fast-paced product development world, the path from concept to scaled manufacturing can make or break your product’s success.

Recently, our team at A3D Manufacturing joined Hawk Ridge Systems at their annual Design to Manufacturing Conference (D2M). Taylor Moore (Director of Manufacturing) and Jacob Moss (VP Operations) spoke about how companies can efficiently transition through different production methods while maintaining consistent quality and appearance. They also shared an automotive customer’s use case to showcase what’s possible and give tangible takeaways for anyone thinking about getting parts made locally and affordably.

Check out the full session: Accelerating Innovation: From Concept to Scaled Production

Key Lessons/Quick Read:

- Design with Intent: Plan for the end goal (e.g., injection molding) upfront to minimize redesigns, overlaps, and costs. Reduces time to market and ensures customer experience consistency.

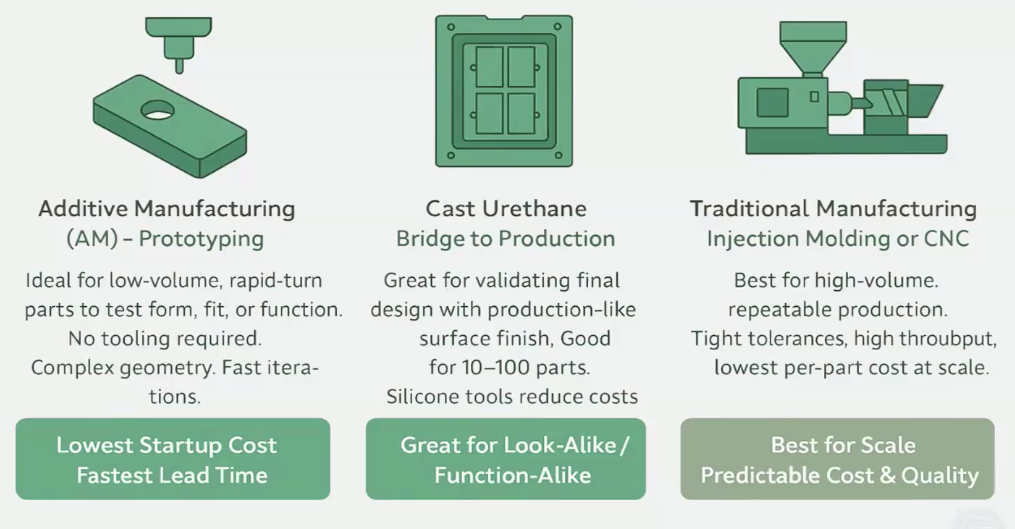

- Cost Management & Scaling: Start with low-startup options (additive manufacturing) to generate revenue quickly, then bridge to mid-volume (cast urethane), and invest in high-volume (injection molding) as sales grow.

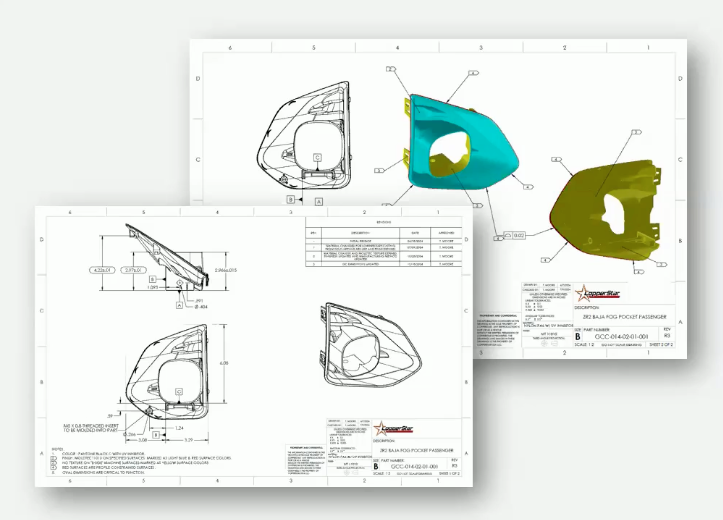

- Documentation Discipline: Detailed drawings communicate critical features, tolerances, materials, and finishes — essential for manufacturers to deliver exactly what you need.

- Communication & Partnership: A3D provides transparency (e.g., production updates) and acts as your supply chain extension. They educate on processes and offer custom testing equipment.

Pros/Cons by Method:

- MJF: Fast, flexible, near-production quality; great for prototypes/low runs

- Cast Urethane: Mid-volume bridge; mold costs lower than steel

- Injection Molding: Cheap per part at scale but high upfront tool costs ($1,000s to $100,000s)

Designing with the End in Mind

One of the most powerful insights we’ve gained from working with successful clients is the importance of designing with intent. Rather than focusing solely on the immediate prototype stage, forward-thinking companies design with their ultimate manufacturing goal in mind.

Consider one of our automotive customers who approached us with an innovative product. What made their project particularly successful was their clarity about the end goal: injection molding. By designing for injection molding from the start, even while beginning with 3D printing, they ensured their customers would experience consistent product quality regardless of which manufacturing stage the parts came from.

Here’s a quick look at how product development evolved for them:

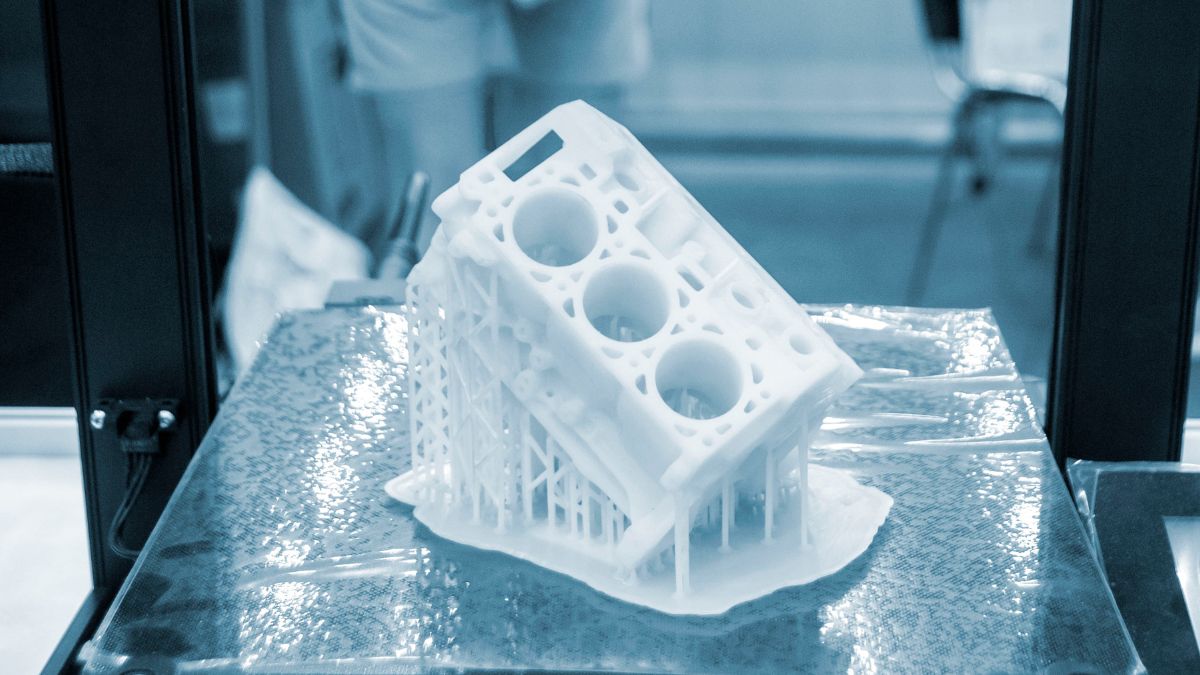

- Prototype Phase (Low Volume): They first used MJF 3D printing for fast, low-cost validation. Parts were ~99% as strong as injection-molded, with finishes (dyeing, vapor smoothing) making them functional, aesthetically pleasing, and immediately useful to the customer.

- Bridge Production (Mid Volume): Then they switched to cast urethane (silicone molds, no heat/pressure) for higher volumes as demand grew. They painted/clear-coated for automotive finish and had quicker mold-making due to initial design intent.

- Full Production (High Volume): Finally, they moved to injection molding (steel tools, high heat/pressure) for 500-2,000+ parts at low per-unit cost. This involved T1 samples (rough initial tests) before final texturing/finishes like UV stabilizers.

Result: Seamless scaling with revenue from early sales funding next steps. Some products stayed in MJF/cast urethane for just-in-time, low-volume needs.

“By designing with the intent of going high volume at the very beginning of the project, you can capitalize on having a consistent design and a consistent experience, not only with your customers but with the manufacturing team.”

-Taylor Moore, Director of Manufacturing

The Strategic Manufacturing Journey

This strategic approach to manufacturing isn’t just about aesthetics — it directly impacts your timeline, budget, and scalability. When you begin with your end goal in mind, you can:

- Reduce validation overlap between different production stages

- Minimize redesign requirements between manufacturing methods

- Deploy capital strategically as your product demand increases

The typical journey for many of our clients follows a logical progression that balances cost with scale:

- Prototype stage with Multi-Jet Fusion (MJF): Low startup costs, fast lead times, and material properties that closely mimic injection-molded parts (achieving 99% of the strength of injection-molded plastics)

- Bridge production with cast urethane: Higher volumes with silicone molds and excellent cosmetic finishes

- Full-scale production with injection molding: Highest volumes with the lowest per-part costs

What’s particularly valuable about this approach is how it allows companies to generate revenue at earlier stages, reinvesting those funds into the next level of production tooling as demand increases.

The Power of Documentation Discipline

While an exciting vision and innovative design are essential starting points, the unsung hero of successful manufacturing partnerships is thorough documentation. Clear, detailed drawings and specifications serve as the critical communication bridge between your design intent and our manufacturing capabilities.

Quality documentation helps our team understand:

- Critical features that must be maintained across all production methods

- Required tolerances for functional components

- Material specifications and their performance requirements

- Finish expectations and cosmetic standards

Without this level of detail, even the best manufacturing partner can’t deliver consistently on your vision. When you provide comprehensive documentation, you’re not just ordering parts — you’re building a partnership based on clear communication and shared understanding.

Scaling Smart: Navigating the Journey from Prototype to Production

A3D Manufacturing is focused on helping engineers overcome challenges like high upfront costs, long lead times, and scaling production while maintaining quality and consistency.

At A3D Manufacturing, we see ourselves as an extension of your team. Whether you’re starting with that napkin sketch or ready to scale to thousands of units, our partnership with Hawk Ridge Systems means you have access to expertise across the entire manufacturing spectrum. A3D aims to help small teams or businesses launch successfully and scale “scrappily” while keeping teams lean.

The best product journeys aren’t just about moving through production stages — they’re about maintaining consistency, controlling costs, and scaling intelligently. By designing with intent, documenting thoroughly, and partnering with experienced manufacturers, you can bring your concepts to market with confidence.

Ready to start your manufacturing journey? Connect with A3D Manufacturing to discuss projects, share CAD, and get instant quotes.