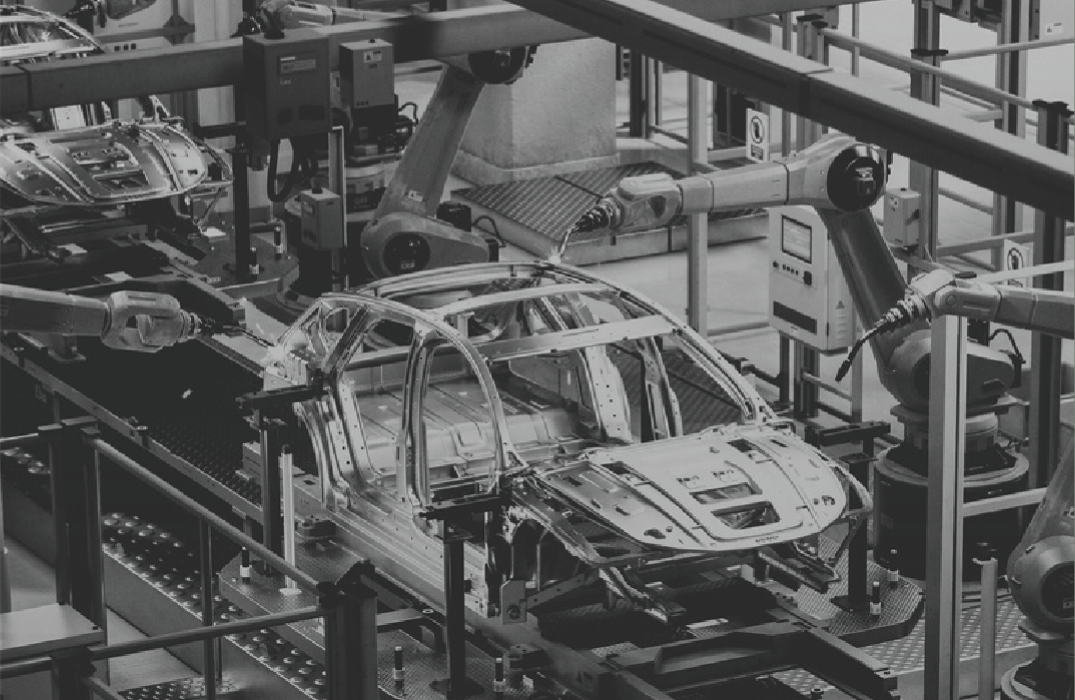

Navigating the complex manufacturing landscape has become a top priority for industries like aerospace, automotive, medical, research, energy, and consumer goods. Challenges abound, from supply chain disruptions to the demand for innovation.

Addressing critical business issues (CBIs) requires new and flexible solutions to gain a competitive edge. Some companies have invested heavily in in-house production, while others find it more practical to utilize a services bureau.

If your business isn’t ready to commit to the cost and resources of 3D printing, or if you prefer a build-as-you go approach for additive manufacturing projects, partnering with a service bureau like A3D can provide access to a wider range of AM technologies.

Questions to ask your team when evaluating your current AM capabilities:

- What types of 3D printing process do you use and what do you have in-house?

- How often are you creating new products?

- What frustrations are you experiencing with current suppliers?

- What would the business impact be if you could go from having production quality parts in days instead of weeks or months out?

Understanding Manufacturing Challenges and Scenarios Where Service Bureaus Add Value

Several challenges come with manufacturing — companies are expected to deliver high-quality products at competitive prices, maintain production schedules despite supply chain disruptions, and continuously innovate to stay ahead of their competition.

Scenarios where 3D printing service bureaus can help:

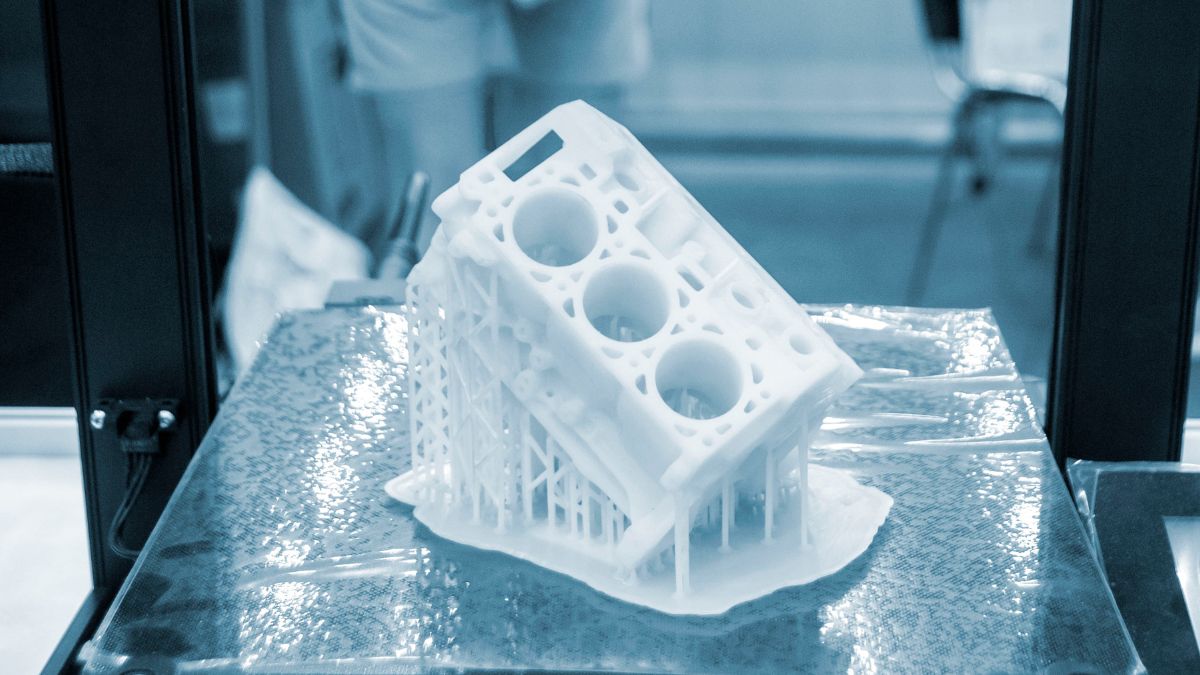

- Low-volume manufacturing: You may only need a few parts at a time, highly custom parts, or perhaps on a project-by-project basis.

- Variance in production needs: You produce a wide variety of products which utilize various materials, requiring different technologies and processes for each part.

- Total cost of ownership: If you don’t have headcount or budget for equipment and post-processing technologies.

- Timeline: You need the parts sooner than you can get AM tech up and running.

Contract Manufacturing: The Benefits of Outsourcing 3D Part Production to Service Bureaus

What are additive manufacturing service bureaus exactly? Service bureaus are third-party organizations specializing in providing manufacturing solutions to other companies.

The benefits of outsourcing production, or part of it, to a service bureau are numerous:

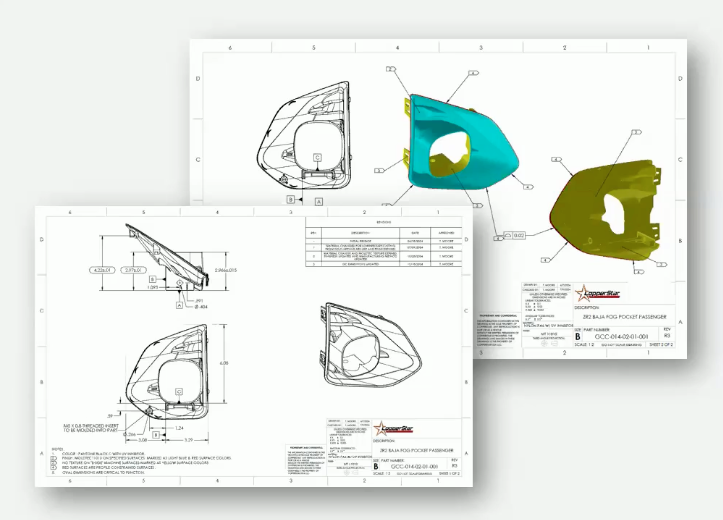

- Expertise: Service bureaus offer deep expertise in manufacturing techniques, such as 3D printing and more specifically metal 3D printing, that might not be available in-house or are cost-prohibitive in nature. By leveraging their knowledge and experience, companies can quickly address business challenges with high-quality manufacturing solutions.

- Flexibility: With service bureaus, companies can benefit from an agile approach to production. Service bureaus can rapidly adapt to changing demands and requirements, ensuring smooth production processes even during disruptions.

- Cost Savings: Outsourcing production to service bureaus allows companies to save on the upfront capital associated with acquiring, operating, and maintaining hundreds of thousands of dollars of specialized equipment. This helps businesses allocate resources more effectively and focus on their core competencies.

- Innovation: Partnering with service bureaus provides companies with access to cutting-edge technologies and the latest innovations in manufacturing. This leads to faster product development cycles and quicker time-to-market for new, more innovative products.

3D Printing Service Bureaus Across Industries

Service bureaus specializing in 3D printing are particularly beneficial for companies in need of rapid prototyping, complex geometries, and on-demand production at scale. 3D printing eliminates the need for expensive tooling and molds and allows for design modifications to be made easily. This technology can also enable the creation of lightweight and durable components with latticed or other complex internal structures, which are essential for sectors such as aerospace, automotive, and medical.

Leverage Capabilities of Service Bureaus So You Can Focus on Core Competencies

Addressing an array of critical business issues is a fundamental part of the manufacturing process. By leveraging the capabilities of service bureaus, companies in the aerospace, automotive, medical, research, energy, and consumer goods industries can navigate manufacturing challenges effectively. Service bureaus specializing in 3D printing offer added value by providing innovative and flexible manufacturing solutions tailored to the specific needs of very diverse sectors of industry.

By outsourcing both prototyping and production to service bureaus, companies can remain focused on their core competencies and ensure that they can deliver high-quality products to the market in a timely and cost-effective manner. With the right manufacturing partners in place, addressing the most critical of critical business issues and achieving lofty business goals becomes more feasible and attainable.

A3D —Your Additive Manufacturing Partner to Scale Your Production

Ready to get started with an additive manufacturing services bureau? At A3D, we specialize in agile, world-class, quick turn additive manufacturing so you can produce high-quality, low-cost products. Our hybrid model includes a network of state-side and offshore facilities for traditional manufacturing processes, offering multiple technologies for various scales of production.

Have questions? Contact us to talk about your project today.