Precision is not optional. It’s a competitive necessity.

When tolerances aren’t met, the consequences can be serious, leading to costly recalls, unexpected downtime, and loss of brand integrity. Poor quality and returned product can cost the average manufacturer millions. And many warranty claims relate to fit or alignment issues, again, pointing back to precision.

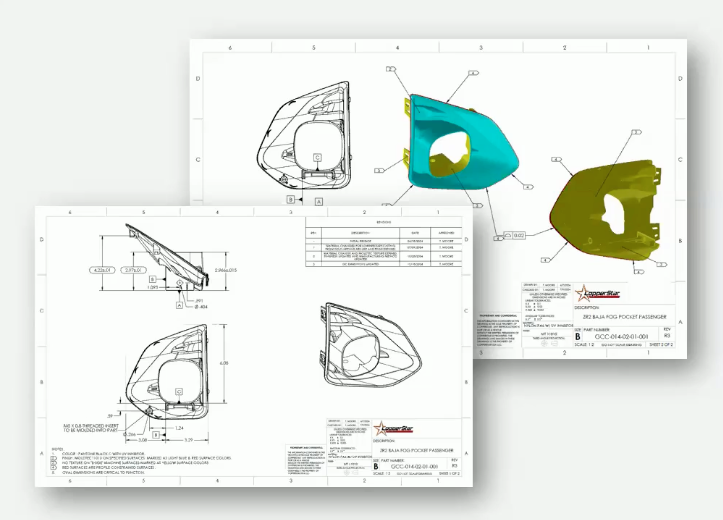

Precision-first practices, centralized quality assurance (QA), and full documentation help automotive aftermarket suppliers avoid these traps. A3D’s Manufacturing as a Service (MaaS) approach offers resources for DFM (Design for Manufacturing) collaboration, quality assurance, and documentation to help you achieve consistent results.

The Not-So-Hidden Cost of Poor Tolerances

When parts deviate from specified tolerances, the ripple effects can vary widely. In automated assembly lines, ill-fitting parts can halt production, but in extreme cases, they can damage expensive assembly tooling and robotics.

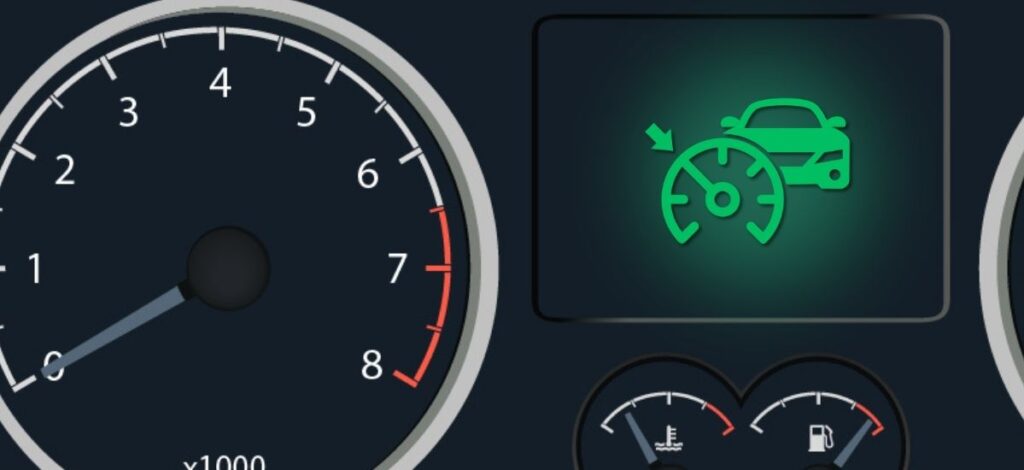

Sensor mounts that are off spec could result in inaccurate readings, potentially affecting vehicle safety systems. In the field, tolerance variations might manifest as premature wear or failures, prompting customer complaints.

In just one notable tolerance failure example, a major automotive brand had to recall its trucks because of a water intrusion issue on its rearview cameras. In the review, they found that the camera connector and the sealing ribs on the coaxial harness connector were both out of tolerance. Mistakes happen, but they shouldn’t. Especially million-dollar mistakes. So how can manufacturers avoid recalls, poor tolerances, and make precision their north star?

- Get the Design Right: Focusing on DFM early helps nail down tolerances and validate designs before committing to expensive hard tooling.

- Make Inspection Your Priority: Metrology and a consistent inspection schema reduce errors and field failures.

- Hyper-Focus on Quality: Find suppliers with documented QA (Quality Assurance) processes.

- Balance Precision & Cost: Not every feature needs plus or minus .001” accuracy. Drawing reviews can identify where to hold tight tolerances and where to relax, saving money without sacrificing performance.

- Ensure Replenishment Consistency: Without traceability and documentation, repeat orders can drift out of spec, potentially creating batch-to-batch variability.

How A3D Solves Challenges Associated with Tolerances and Precision

Decreasing Downtime

Every order runs through A3D HQ pre-ship QA with a standard inspection every time, though more advanced inspection programs are available, ranging from simple inspection reports to AS9102 FAIRs, accuracy heat maps, and sampling plans. Parts arrive release-ready, reducing the risk of line stoppages.

Reducing Scrap & Rework

A project consultation will ensure the manufacturing method matches the requisite tolerances and also gives an opportunity to red-flag challenging features that would increase scrap rate.

Increasing Traceability for Quality Resolution

A robust MES (Manufacturing Execution System) utilizing detailed travelers means each process step is signed and dated. If issues arise, suppliers have full traceability, which is a powerful tool to aid in root cause analysis and finding a resolution.

Making Inspection Easier

Upon request and/or with an inspection add-on, A3D can send a Material Certificate (including lot number), Certificate of Conformance (these two are free), First Article Inspection Report, PPAP, CPK Study, inspection heat map, and a custom sampling plan report.

Consultative Lifecycle Reviews

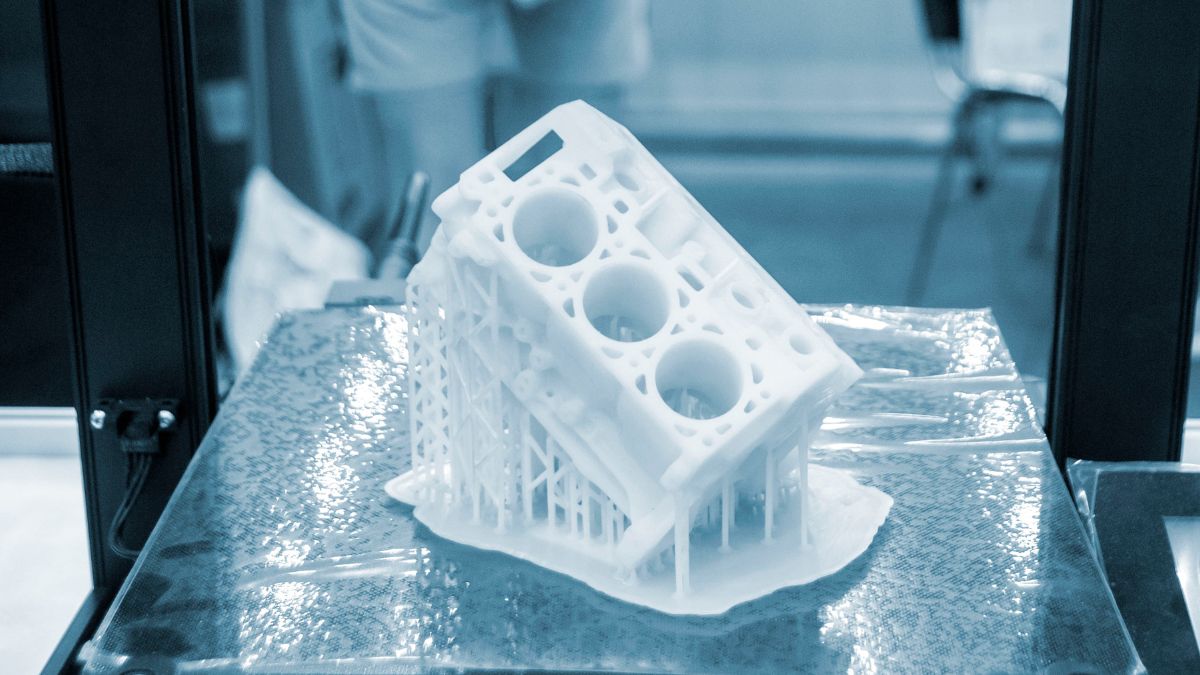

A3D aligns tolerance needs with manufacturing methods, using risk reduction tools like prototypes, soft tooling, or first articles to avoid premature tool spend.

For example, A3D has an electronics customer that builds fixture brackets to hold PCBs. Originally, they wanted to use FDM (Fused Deposition Modeling) 3D printing capabilities to ensure a tight fit for the build, but after consultation, we found it was actually more cost-effective to use injection molding. A3D crunched the numbers and found that FDM and Injection Molding had a comparable lead time for production (thousands of parts), but going with Injection Molding meant a 71% overall cost reduction. On subsequent re-orders, it would be a 93% cost reduction.

Read more A3D Manufacturing customer stories.

Partner Blind Spots

Quotes from A3D Manufacturing are application-first, not just price-first. Every build is DFM-reviewed with process recommendations and viable alternatives, so we can define a realistic build plan.

Precision is Not Optional: Partnering for Reliable Tolerances and Reduced Risks

Selecting the right manufacturing partner is key when you value precision. Look for:

- Upfront DFM insights

- Same-day DFM-reviewed quotes

- Quotes that include alternative materials and capability options (flexible engagement options)

- Clear inspection plans, full documentation plans

- Centralized quality controls

- Comprehensive documentation to support compliance and traceability

- Proximity to your operations to minimize supply chain delays

The goal here is mutual alignment — ensuring the partner’s practices complement your supply chain and reduce risks like variability or non-compliance.

Why A3D is the Automotive Aftermarket Manufacturer Partner of Choice

Poor tolerances aren’t just a quality issue — they’re a cost center. Ill-fitting parts, sensor interference, or premature wear mean scrap, downtime, warranty claims, and lost trust. A3D safeguards precision with same-day DFM-reviewed quotes, centralized QA at A3D HQ, and a QA deliverable that suits your needs.

At A3D Manufacturing, we have two paths to build: Auto checkout for additive orders and consultative for those projects with that added layer of complexity.

- Auto-Checkout for Additive: Fast, self-serve directly from the website for new orders and replenishment (same plan, same docs.)

- Consultative Review for Complex or Traditional Manufacturing: Requirements reviews, DFM, and production-lifecycle planning when precision, documentation, or multi-process needs are in play.

No matter the path you choose, you get the best quote, quality assurance, and the documentation you need to support it. Contact A3D Manufacturing.